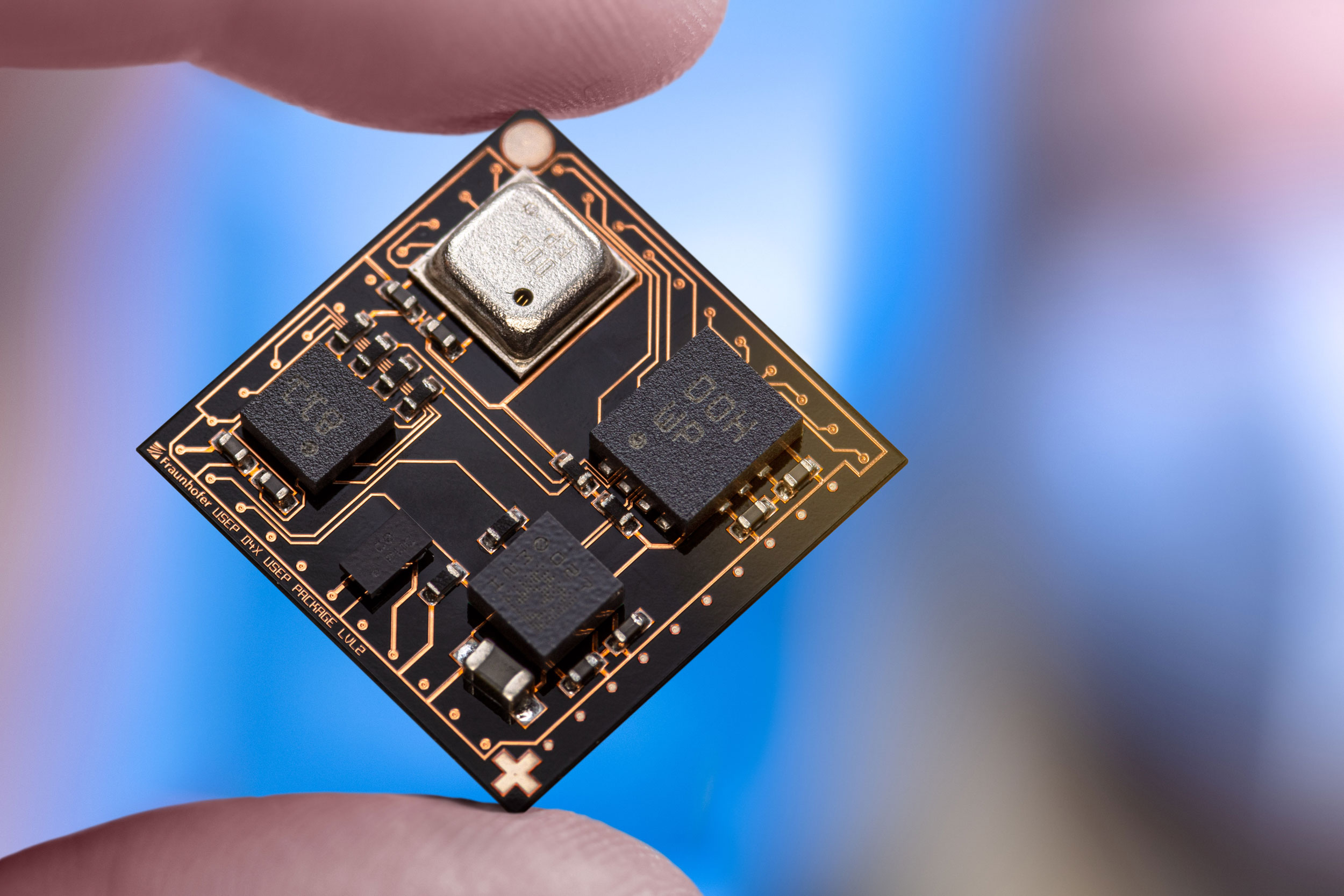

An innovative sensor platform 'Made in Saxony' enables even small companies to develop IoT systems cost-effectively.

High technology for medium-sized businesses: Lower costs for more creativity

Together with Globalfoundries Dresden, a network of Fraunhofer institutes in Saxony has developed a sensor platform that can be used to create individually configurable IoT and edge computing solutions. This means that, for the first time, small and medium-sized suppliers now have the opportunity to produce particularly powerful, energy-efficient and highly integrated systems at low cost. In contrast to independent development, the time required and development costs are significantly reduced.

How can we develop a highly integrated, multi-channel sensor solution for mechanical engineering? Or a networked sensor system for building automation? For small and medium-sized enterprises (SMEs), developing smart systems that are tailored to requirements, miniaturized and adapted to individual specifications is a complex and expensive undertaking: They cannot use off-the-shelf electronic modules. Instead, they have to design innovative system solutions for selected customers themselves, usually in small quantities.

"Clients increasingly expect highly integrated electronic prototypes or small series for the Internet of Things (IoT) and edge computing. Without the appropriate system architectures and manufacturing methods, however, it is difficult for medium-sized companies to achieve a return on investment in development," says Dr. Peter Schneider, head of the Adaptive Systems Development EAS branch of the Fraunhofer Institute for Integrated Circuits IIS in Dresden.

Support for SMEs as drivers of innovation

Under the leadership of the EAS section of the institute, a consortium of Saxon Fraunhofer institutes and industry has therefore developed the "Universal Sensor Platform USeP". It enables SMEs in particular to use a wide variety of modular and configurable platform elements and to assemble them according to the modular principle with a maximum of flexibility. "The 3D sensor platform gives developers a largely free hand in terms of both software and hardware to manufacture forward-looking, individual products. Whereas in the past this usually cost six- or seven-digit euro amounts, SMEs can now save up to 90 percent in time and costs under certain circumstances," explains Schneider. Thanks to the good and intensive cooperation between the development partners involved, the successful completion of the trend-setting project was made possible within just three years. USeP has already passed its first practical test. Within a cooperation between Globalfoundries Dresden and five other companies from the hardware and software sectors, it was the core of an edge AI pilot solution. With its help, the companies were able to develop a first product version (Minimum Viable Product) for predictive maintenance of ultra-pure water valves in chip production within just three months.

Construction kit for high-tech development

"The sensor platform based on GLOBALFOUNDRIES 22FDX® technology developed in Dresden enables an energy-efficient yet high-performance SoC (system on chip) design that meets demanding edge computing requirements with embedded MRAM," says Dr. Axel Preuße of Globalfoundries Dresden. The chip features numerous wireless and wired communication interfaces and uses a powerful 32-bit RISC-V processor with a total of 9 cores as the central computing and control unit. This open-source processor architecture is regarded as cutting-edge, not least because of its openness and flexibility, and provides the ideal basis for secure and trustworthy electronics. The platform's unique system architecture is also characterized by the fact that it combines state-of-the-art assembly and packaging technologies with the latest semiconductor design methods and security components. Thanks to its flexible building blocks and the associated software environment, it enables uncomplicated integration of different sensors.

In the meantime, the research project supported by the Free State of Saxony and the European Union within the framework of the European Regional Development Fund (ERDF) has been completed and an independent company has emerged: The start-up Sensry in Dresden not only offers its customers the opportunity to tailor highly integrated sensor electronics modules using the Universal Sensor Platform, but can also provide interested SMEs with the expertise of USeP development partners. This provides them with a supply chain with which they can efficiently implement their ideas and visions: Concept development, system design, processors, sensor technology and data transmission as well as simulation and testing of their planned system are supported comprehensively and sustainably.

In addition to the semiconductor manufacturer Globalfoundries Dresden, the Saxon Fraunhofer Institutes for Photonic Microsystems IPMS and Electronic Nano Systems ENAS, as well as the All Silicon System Integration ASSID division of Fraunhofer IZM and the Development of Adaptive Systems EAS division of Fraunhofer IIS were involved in the development of the Universal Sensor Platform USeP. The research partners were supported by colleagues from Fraunhofer IZM in Berlin, Fraunhofer IIS in Erlangen and Fraunhofer AISEC in Garching near Munich.

Joint press release on the conclusion of the "USeP" project

Project partner:

- Globalfoundries Dresden

- Fraunhofer ENAS

- Fraunhofer IIS/EAS

- Fraunhofer IPMS

- Fraunhofer IZM-ASSID

The use of the photos is permitted exclusively in connection with this press release and with indication of the copyright.

Fraunhofer Institute for Photonic Microsystems

Fraunhofer Institute for Photonic Microsystems