Future Mobility: Green mobility "made in Saxony"

Applications in the field of moblity

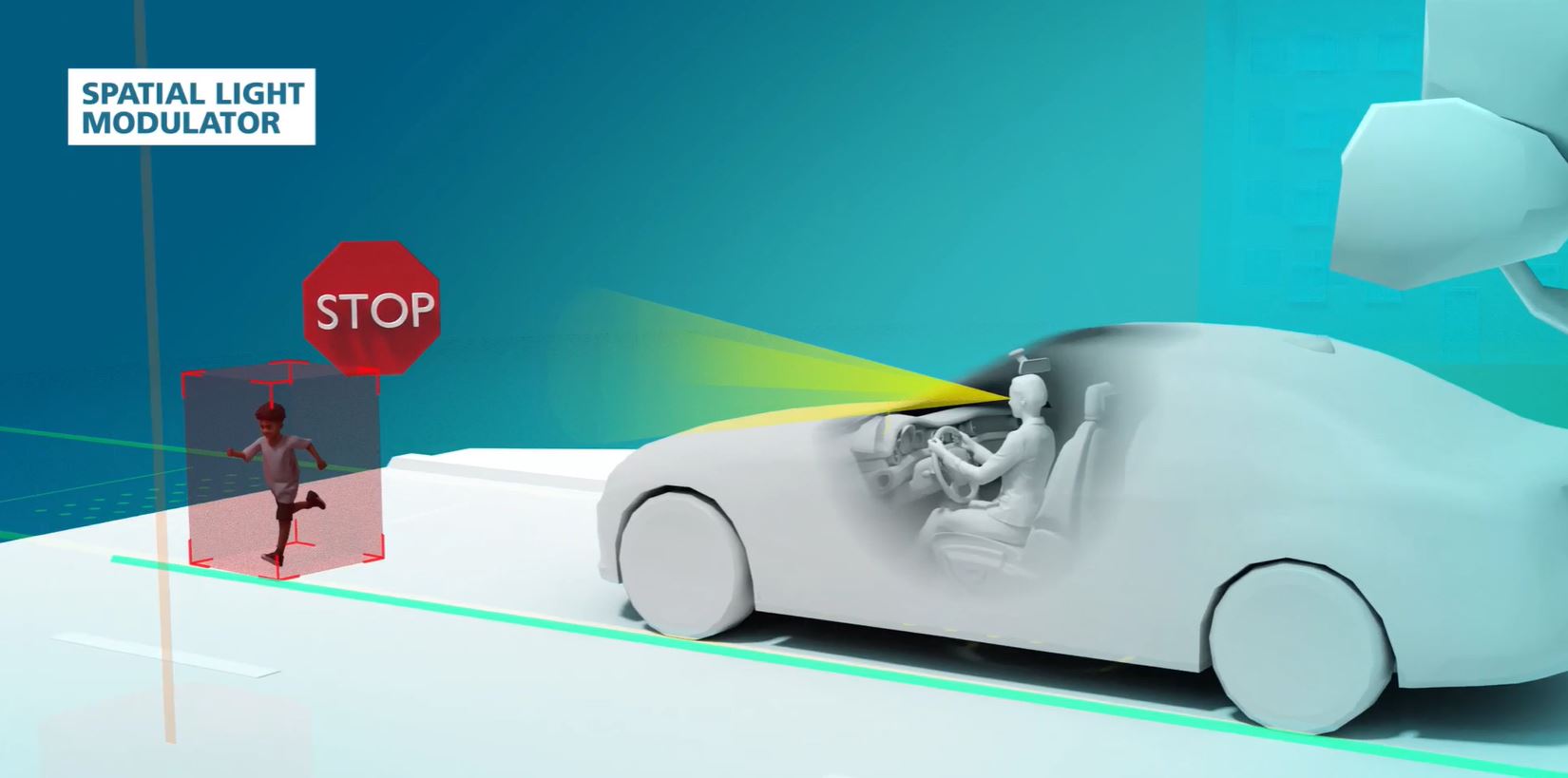

Rapid urbanization and globalization, along with increasing environmental challenges, demand bold solutions, especially in decarbonization (with a focus on mobility) and digitalization. In response, the Future Mobility consortium project, led by Infineon Dresden, aims to develop innovative technologies across the entire value chain. From product design and development to process innovation and technology development and high-volume manufacturing, the goal is to enable next-generation power products and automotive electronics systems.

Fraunhofer IPMS plays a central role in this effort, focusing on energy-efficient technology development and high-reliability process innovation to support advanced mobility applications.

Key work packages at Fraunhofer IPMS:

- Next-generation material layers: We're developing new coating techniques that ensure even the smallest structures on microchips are perfectly covered, which is essential for performance and miniaturization.

- Smarter metal connections

Our work includes improving how tiny metal contacts are added to semiconductor structures, making them more reliable and energy-efficient. - Surface perfection for high performance: We’re refining polishing processes to create smooth, defect-free surfaces, reducing electrical resistance and improving durability.

Together with project partners, Fraunhofer IPMS is shaping the quality standards of tomorrow - supporting battery longevity, power loss reduction, and system performance. Simulation, real-time monitoring, and smart process control contribute to a sustainable, people-centered production environment, aligned with the goals of digital transformation and green mobility

Fraunhofer Institute for Photonic Microsystems

Fraunhofer Institute for Photonic Microsystems