L-CMUT

Among sensors, ultrasonic transducers are the all-rounders that have established themselves for many detection tasks in technical applications. The use of sensor systems for the exchange of information in the near-distance and contact range is becoming increasingly important. For example, in gesture recognition or collision warning. The application area of gesture recognition in particular increasingly requires miniaturised sensors with low energy consumption in order to integrate them into mobile internet-enabled end devices.

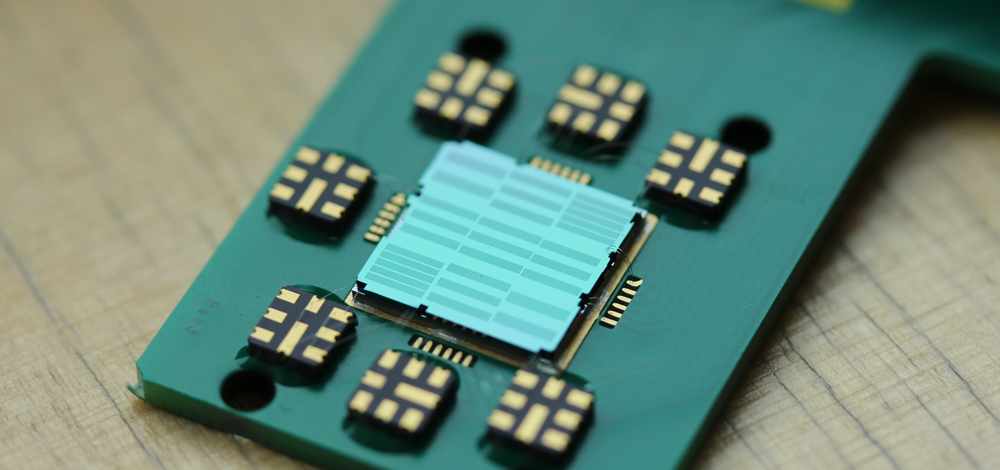

The novel ultrasonic transducers in MEMS technology, which were developed in the business unit Monolithically Integrated Actuator and Sensor Systems of Fraunhofer IPMS, can close this gap. The technology makes it possible to dispense with the membrane used in conventional ultrasonic transducers. Instead, microscopically small bending bars are used, which are set into vibration by a signal and oscillate in the chip plane. In order to generate sound, these bending beams are arranged in sound chambers and the sound exits the sound chambers via inlet and outlet slits.

Fraunhofer Institute for Photonic Microsystems

Fraunhofer Institute for Photonic Microsystems