Integrated Micro Batteries

Another research topic at Fraunhofer IPMS is integrable microbatteries. With the increasing energy efficiency of microelectronic circuits, the required energy storage devices can also be made ever smaller. It is foreseeable that this development will continue. This means that the direct integration of the energy storage device into the chip can also be a cost-effective and effective solution. This technology is particularly interesting against the background of the Internet of Things, as it enables maintenance-free sensor nodes, for example.

Compared to integrated capacitors as energy storage devices, batteries in the form of an eletrochemical redox couple have the advantage that the discharge curve has a large window with an almost constant voltage curve. This makes the transfer of energy to consuming circuit parts much easier and with lower losses. Another advantage is the very low discharge currents, which guarantee a correspondingly long availability of the stored energy.

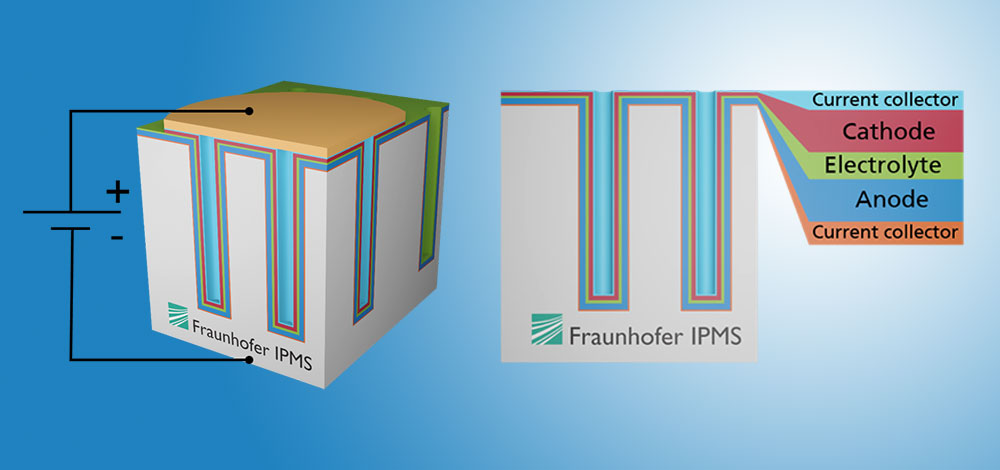

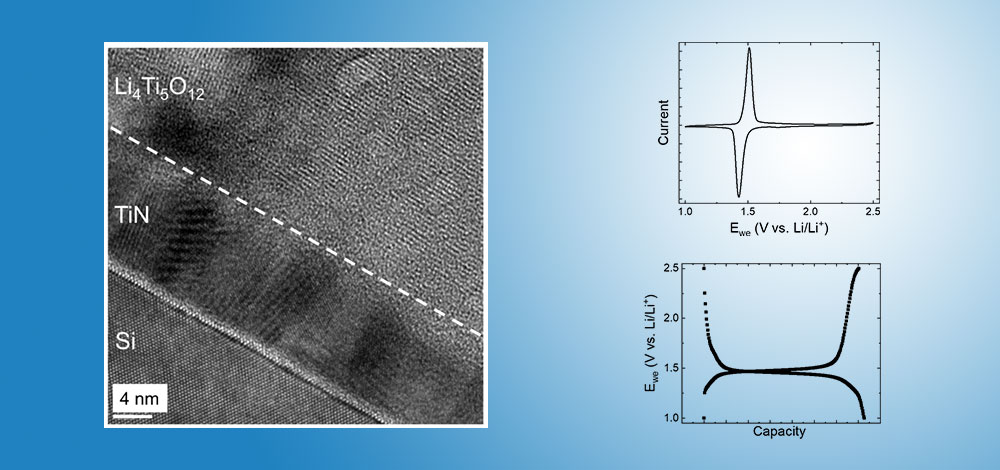

However, conventional batteries require a lot of space and volume. To realise such a concept on a chip, whose costs depend precisely on the surface area, is the great challenge. The Fraunhofer IPMS is therefore using its many years of experience in 3D structuring of silicon to integrate the battery stack as deeply as possible into the silicon and thus save chip area. To do this, micrometer-deep holes with diameters of less than a hundred nanometers must be coated completely uniformly. With the processes developed at the institute, even complex battery materials can be created in such structures with accuracies in the sub-nanometer range. This will make it possible to create completely new, self-sufficient semiconductor systems in the future.

Fraunhofer Institute for Photonic Microsystems

Fraunhofer Institute for Photonic Microsystems