Fraunhofer IPMS is part of project QUASAR

Towards a quantum processor “made in Germany”

The quantum computer race is in full swing. Germany has long been one of the world leaders in basic research. In the joint project "QUASAR", the Fraunhofer Institute for Photonic Microsystems IPMS now wants to develop a semiconductor quantum processor "Made in Germany" together with its partners. The project, which is funded by the German Federal Ministry of Education and Research (BMBF) with more than 7.5 million euros, aims to lay the foundations for the industrial production of quantum processors over the next four years

Quantum computers have the potential to outperform conventional supercomputers by far in certain problems, for example when it comes to controlling traffic flows in metropolitan areas or simulating materials at the atomic level. But it is still unclear which approach will win the race among quantum computers. Experiments with superconducting qubits, the smallest units of a quantum computer, are currently the most advanced. For example, Google’s quantum chips and the experimental quantum computer in the European Quantum Flagship project, which is to go into operation this year at Forschungszentrum Jülich, are based on them. But when it comes to large numbers of qubits, semiconductor qubits may have the advantage.

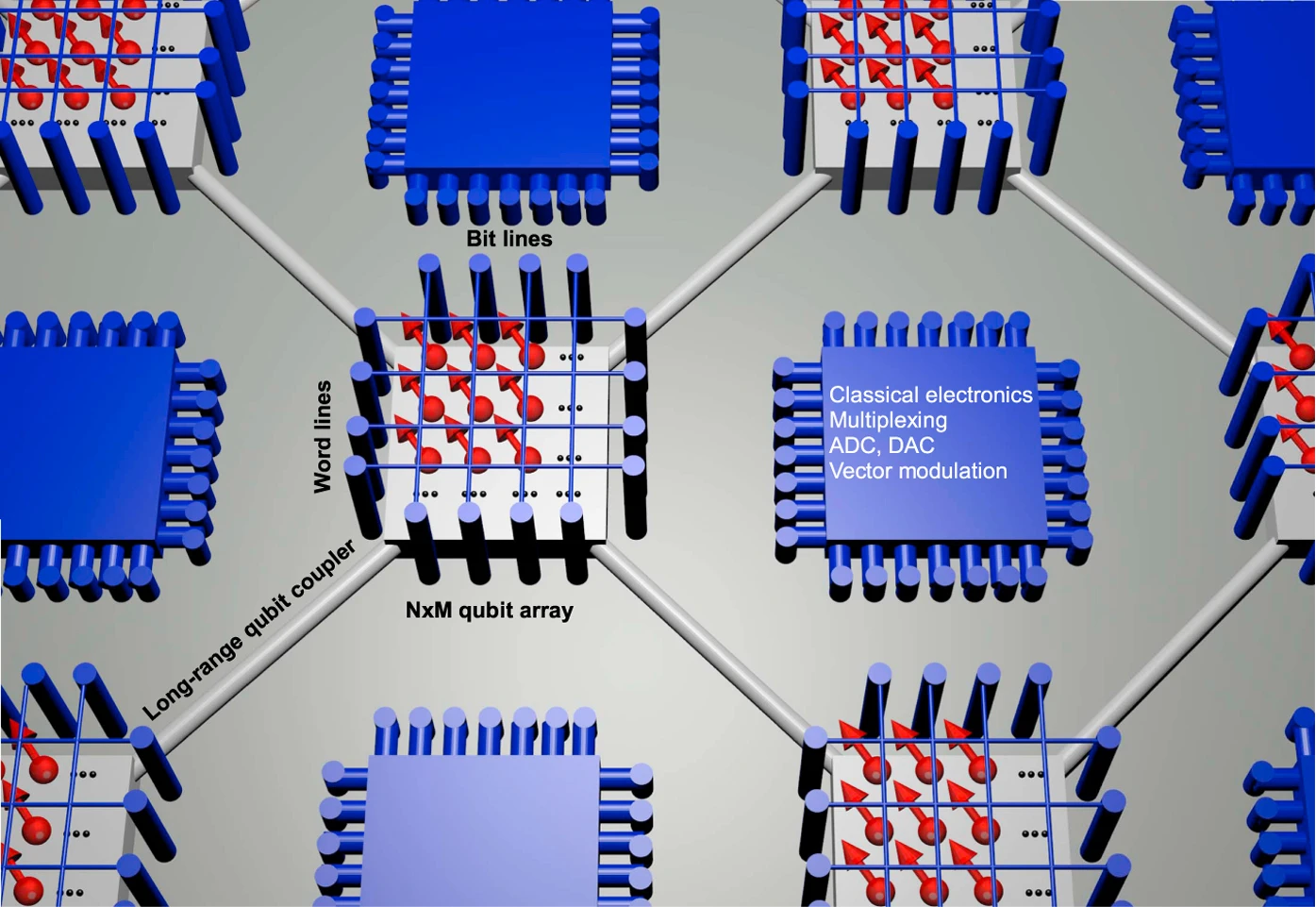

Silicon electron spin qubits are one promising system for semiconductor qubits because they have comparatively robust quantum properties and are much smaller in size than superconducting quantum bits. However, geometric limitations have so far prevented them from being easily scaled like classical computer chips. The qubits have to be very close to each other in order to couple them. To achieve this, Forschungszentrum Jülich and RWTH Aachen University, together with partners, developed a so-called quantum bus in a preliminary project. This special interconnection element allows distances of up to 10 micrometres between the individual qubits to be bridged efficiently. The quantum bus can capture the electrons on these quantum dots and transport them in a controlled way without losing the quantum information.

Towards industrial scalability

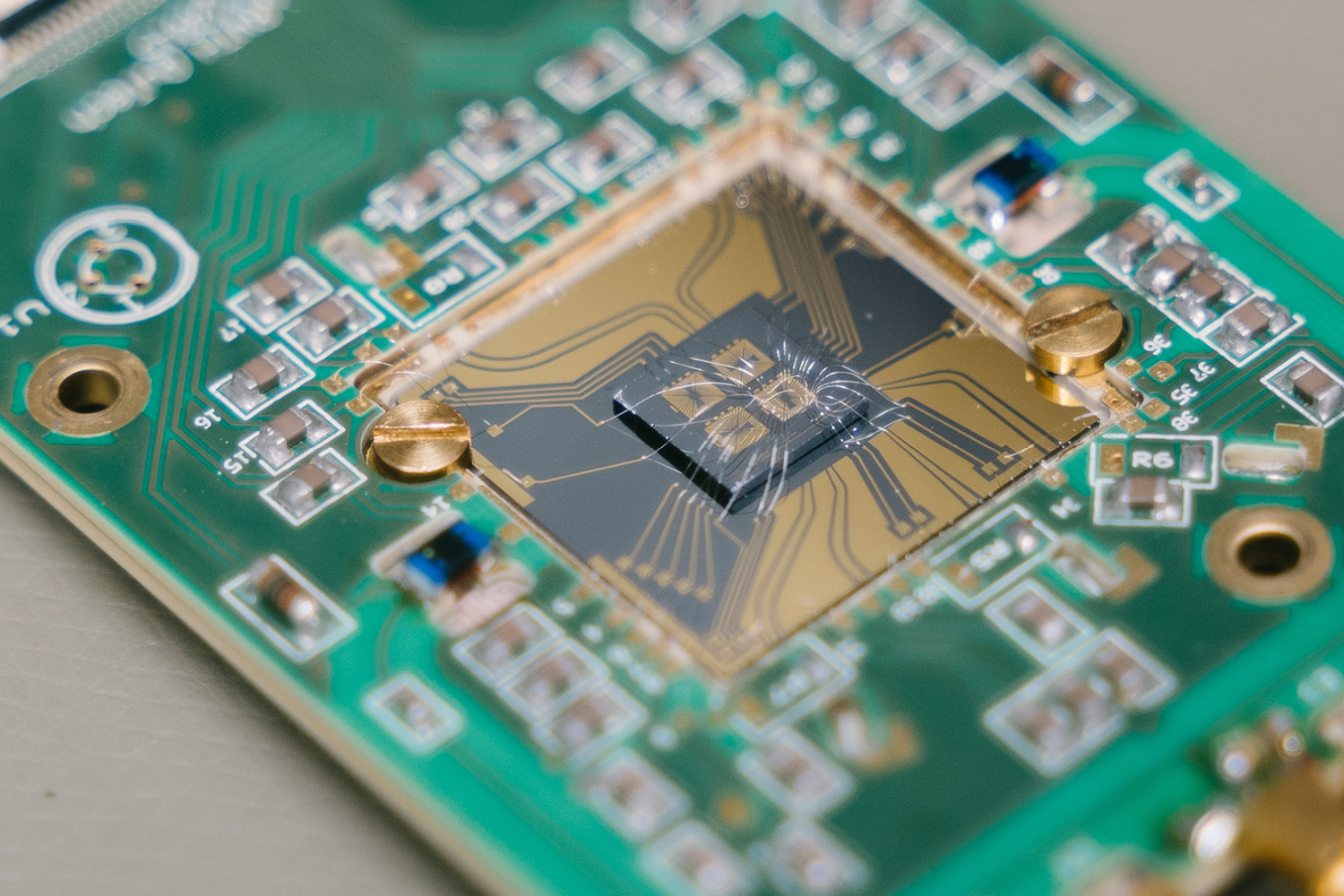

In the laboratory, experimental samples have already shown promising results. In order to adapt this approach to industrial manufacturing processes, FZ Jülich and RWTH Aaachen have joined forces with Infineon Dresden, start-up HQS, institutes of the Fraunhofer-Gesellschaft (IAF, IPMS) as well as the Leibniz Association (IHP, IKZ) and the universities in Regensburg and Konstanz.

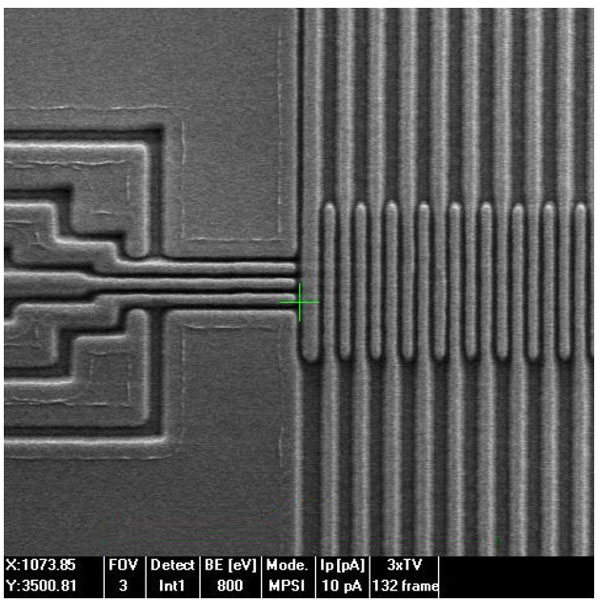

Fraunhofer IPMS contributes its expertise from CMOS fabrication and, based on its many years of experience in electron beam lithography and in close cooperation with Infineon, will deal with the fabrication of the complex "Gate 1" quantum gates. Optimized device structures with the highest possible homogeneity at the substrate level will be made available via several interration steps, taking into account industrial manufacturing processes. This could not be achieved with conventional laboratory methods such as lift-off processes in the required quality and quantity in terms of structure scalability.

The use of the photos is permitted exclusively in connection with this press release and with indication of the copyright.

Fraunhofer Institute for Photonic Microsystems

Fraunhofer Institute for Photonic Microsystems