NED technology from Fraunhofer IPMS is expanding the fields of application for hearables

From Invention to creation – how Fraunhofer IPMS applied an innvoation by founding the Arioso spin-off company

Fraunhofer IPMS founded the spin-off company Arioso Systems GmbH in October 2019. The aim of founding this company was to launch an innovative sound transducer principle for miniaturized headphones (also known as ‘hearables’) onto the market. These voice-operated, multi-talented devices are worn in the ear and will even be able to completely take over Internet communication in the future thanks to their unique Nanoscopic Electrostatic Drive (NED) technology from Fraunhofer IPMS. We spoke to Dr. Herrmann Schenk, Chief Operating Officer of the spin-off company, about the reasons behind this.

What aim is Fraunhofer IPMS pursuing by founding this spin-off company?

Entrepreneurial spirit is important for cutting-edge technology. With our spin-off company, we wanted to introduce completely new audio technology to the market and thereby make our contribution to the competitiveness of Germany’s industry. The business purpose of the IPMS spinoff company Arioso Systems GmbH is especially aimed at developing, manufacturing and marketing micromechanical transducers for audio applications using NED technology.

How did the idea for the innovation come about?

It all started with the invention of a new type of microelectro-mechanical bending actuator. Actuators convert electrical signals into mechanical movements and are absolutely essential in electronics. Our expert Holger Conrad was given the task in his examination paper of converting electrical current on a semiconductor chip into movement. For this, he had to produce a micromirror made from piezo materials that bend under electrical load, which could be controlled electronically. As this did not work, Holger Conrad attempted to convert the electrical current into movement directly on the silicon chip. In this way, he developed the Nanoscopic Electrostatic Drive (NED) principle. The idea is spectacular: thanks to the NED principle, large displacements are already being achieved under currents of a lot less than 50 volts. By cleverly arranging the electrostatic cells, movement on the chip can occur continuously. This enables it to be used as a transducer, even producing high audio quality.

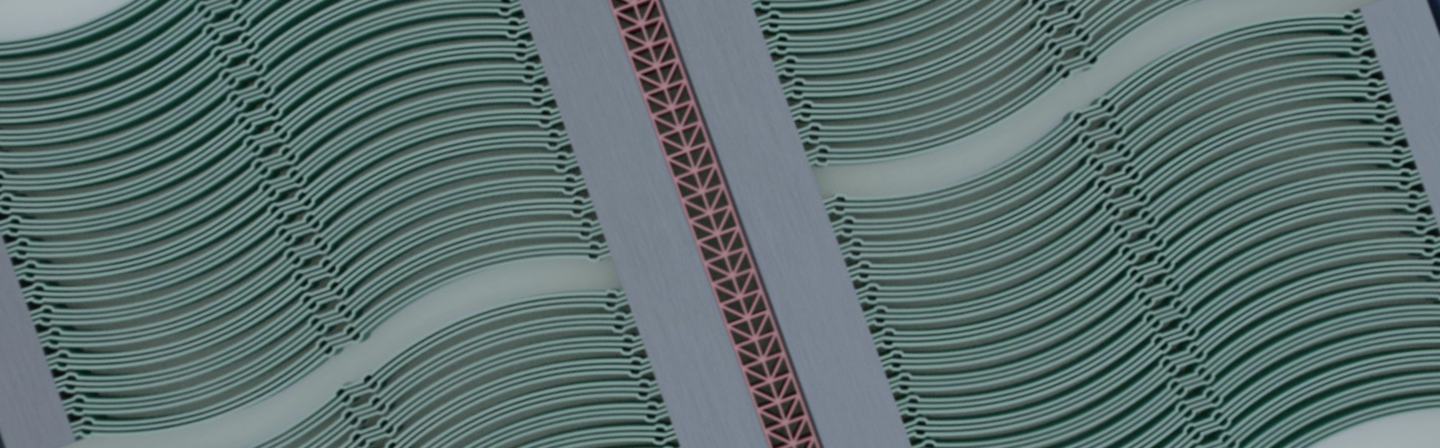

How does the NED actuator principle work specifically in a loudspeaker?

The new transducer principle no longer has a conventional membrane. Instead, the membrane is installed inside the body of a silicon chip, arranged to some extent as bands and in the form of a series of bending strips similar to the strings on a harp. With their integrated, electrostatic drive, the 20 μm thick bending strips form a completely new class of electrostatic bending actuators. The NED actuators are energized into producing vibrations by applying an audio signal voltage. In order to prevent acoustic bypass on both sides of the strips, the Development Team led by Bert Kaiser and Sergiu Langa attached silicon wafer layers to the base and cover with cleverly arranged outlet and inlet slots on the upper and lower sides of the bending strips. This enables the micro loudspeaker to be produced completely using silicon technology.

How is the invention used in the ear?

The idea for applying in-ear NED technology came from our Institute Director Professor Dr. Harald Schenk. Sound sources generate pressure waves in the air, which cause our eardrums to vibrate. We perceive these as sounds. I seal off my ears with in-ear headphones, then the loudspeaker generates airwaves and my eardrum vibrates. In this way, the amount of air moved influences the volume of the sounds, i.e. the sound pressure. The NED actuators function like vibrating strips, which displace the air with their movement, thereby stimulating the eardrum. The new technology facilitates sound pressures of up to 120 decibels; only around 0.5 mm³ of air has to be moved in the ear canal in order to produce such high sound pressures. The advantage of silicon technology is the NED loudspeaker’s high scale of miniaturization, enabling the space created in the headphones to be used for further functionalities.

What applications are possible in addition to audio transmission into the ear?

The technology’s high scale of miniaturization and energy efficiency open up completely new types of mobile applications. Just like having “Alexa in your ear”, smart hearables enable numerous Internet applications such as payment services and translations, which are all voiceoperated without any need to look at a smartphone. The new transducer principle is also attractive for use in hearing aids.

How is Fraunhofer-Gesellschaft supporting the spin-off company?

The Fraunhofer principle is to enable knowledge to be applied. Fraunhofer-Gesellschaft initially provided 25 % of the company assets to the Arioso start-up and licensed NED technology for the “audio” field of application exclusively for Arioso. Furthermore, Fraunhofer IPMS has an excellent infrastructure for producing NED micro loudspeakers in small batches amounting to several tens of thousands every year. This capacity is indispensable for Arioso’s successful market entry and will surely be requested by Arioso’s customers.

What are the next steps for the spin-off company?

The start-up was initiated with a great promise of success thanks to the first-rate work by the scientists and cleanroom engineers from Fraunhofer IPMS. The market is highly interested in MEMS-based micro loudspeakers. We are currently engaging in discussions with companies that would like to develop product perspectives for the different applications by working together with us. For Arioso, this means that we want to establish functions and produce pilot series. In doing so, Arioso has developed a very promising commercial basis. I am therefore highly optimistic and looking forward to seeing further developments from Arioso Systems GmbH.

Thank you very much for the interview!

Fraunhofer Institute for Photonic Microsystems

Fraunhofer Institute for Photonic Microsystems