Intelligent Actuator Systems for Precise Modulation and Control

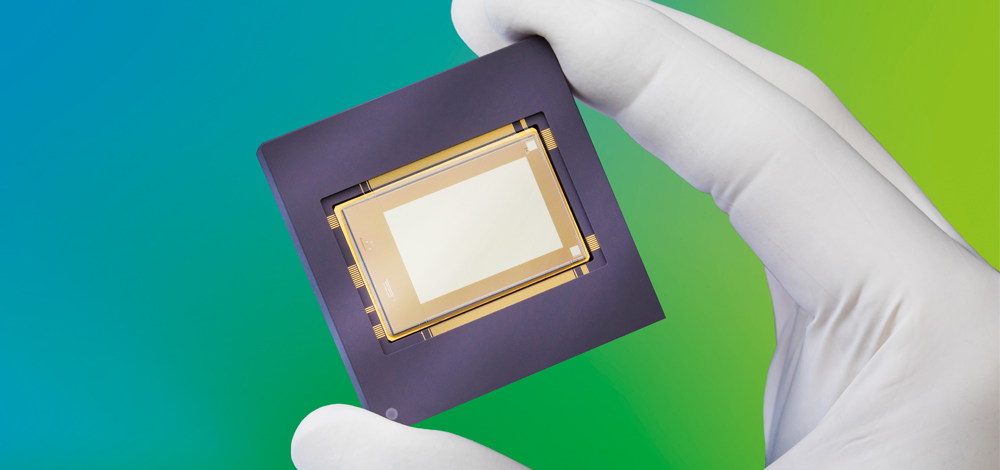

Fraunhofer IPMS develops compact actuators and actuator systems that combine electrical, mechanical, and optical functions. Our solutions enable precise motion control and regulation, for example, in optical systems using MEMS scanning mirrors or spatial light modulators.

Using technologies such as MEMS, CMOS, and integrated system electronics, we offer customized, energy-efficient actuators for industrial and specialized applications - from concept development to pilot manufacturing.

Fraunhofer Institute for Photonic Microsystems

Fraunhofer Institute for Photonic Microsystems