Intelligent Actuator Systems for Precise Modulation and Control

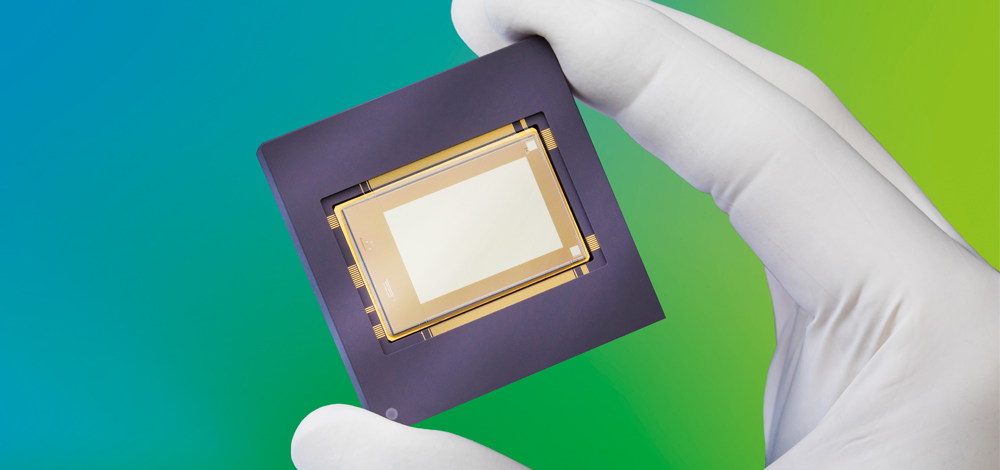

Fraunhofer IPMS develops and manufactures actuators based on MEMS and NEMS technologies that enable precise, reproducible, and energy-efficient motion and positioning functions. Our actuators employ electrostatic, piezoelectric, and electromagnetic drive principles and can be tailored to specific requirements regarding force, displacement, frequency, and level of integration.

These systems are integrated into complex microsystems and enable functions such as beam steering, focusing, micropositioning, or acoustic signal conversion. Combining expertise in materials, design, and fabrication, Fraunhofer IPMS offers customized solutions — from concept development and design to small-series production under industrial conditions.

Fraunhofer Institute for Photonic Microsystems

Fraunhofer Institute for Photonic Microsystems