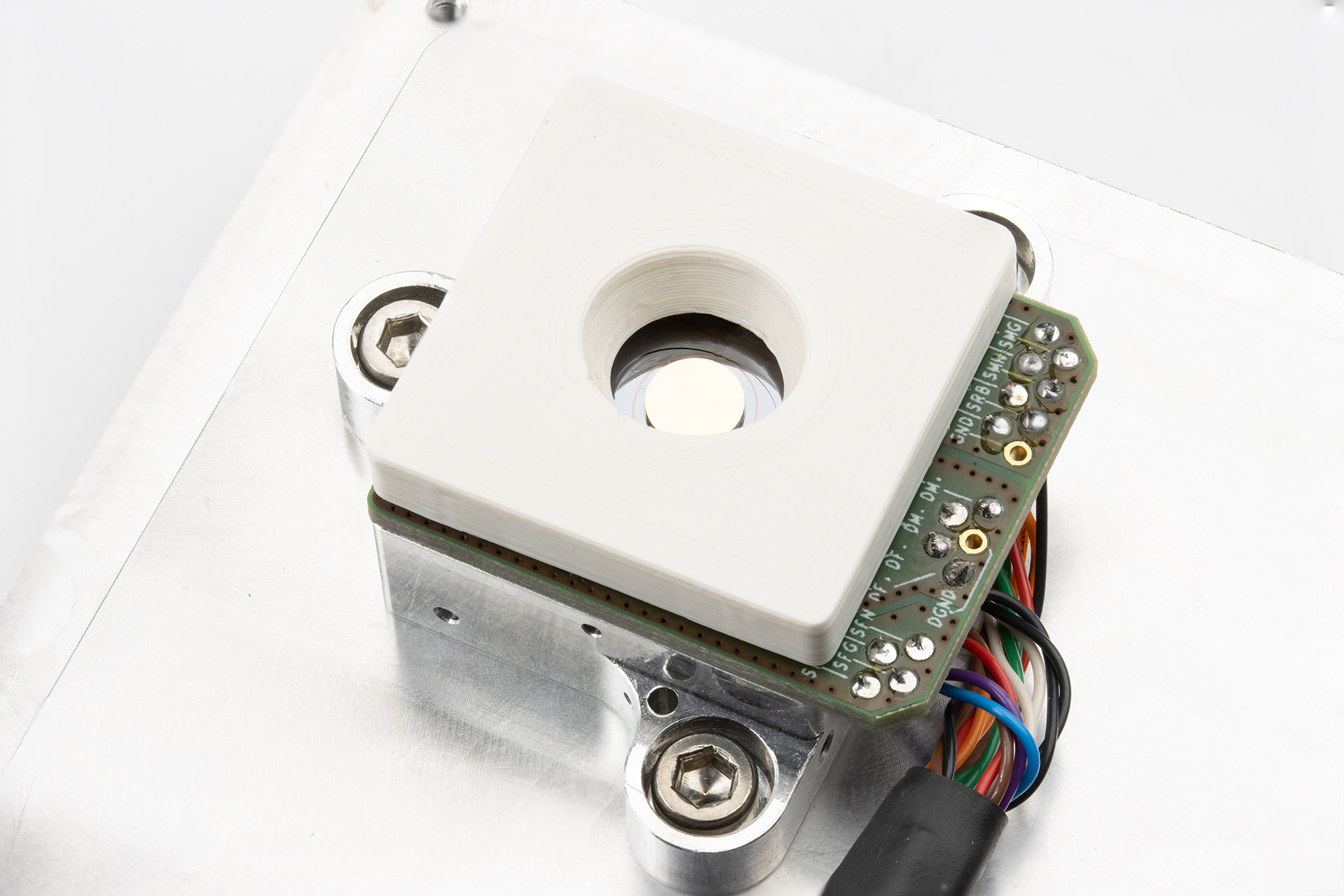

We develop MEMS vectorscanner mirror for LiDAR applications and optical communication.

Our hybrid vector scanner technology offers ready-made and customized solution for fast and precise beam deflection. It enables large apertures and large deflections compared to previously available MEMS technologies, while being robust against environmental conditions (temperature, vibration, shock).

Do you need a precise and robust beam deflection solution? Do you want to maximize your light output or do you only have a poor beam quality available for economic reasons and therefore see a need for a large aperture? Does your application also require large beam deflections in a robust package? Then you have found the right scanning solution!

Fraunhofer Institute for Photonic Microsystems

Fraunhofer Institute for Photonic Microsystems