Fraunhofer IPMS presents innovative microsensor solutions at the SENSOR+TEST trade fair

High-precision microsensor technology for a wide application range

Developing pioneering technology solutions and bringing them into application - that is the goal of Fraunhofer Institute for Photonic Microsystems IPMS. At this year's SENSOR+TEST trade fair in Nuremberg, the institute will present its latest developments in optical, chemical and ultrasonic sensor technology.

Due to the high demand for sensors in a wide variety of application fields, there are very different requirements for their functionality and performance profile. The core objective of the research work of Fraunhofer IPMS is therefore to develop customer and application-specific systems. In doing so, existing products are expanded and new applications are made possible through the use of innovative technologies, components and systems. These are characterized by higher precision, smaller dimensions, better energy efficiency and additional functions compared to standard sensors. The range of services extends from conception and prototype development to pilot production in the institute's own laboratories and clean rooms - from components to complete system solutions. The combination with artificial intelligence (AI software) also enables the development of "intelligent" complete systems.

Optical sensors

Visitors to the trade fair stand of the Fraunhofer IPMS will receive information about innovative compact and ultra-compact near-infrared (NIR) spectral analysis systems. In addition, the institute is presenting for the first time a demonstrator that uses spectral analysis to detect the composition of textiles. The area of application opens up numerous possibilities along the entire value chain. In this way, the materials can be checked by the buyer at the time of purchase. In the area of care, the need for cleaning can be identified by analyzing the dirt particles, and a suitable washing program can be determined on the basis of color and materials. Especially in the context of Ambient Assisted Living, versatile areas of application are conceivable. The system can also be used in relation to textile recycling to sort textiles according to color and materials.

Other areas of application for the Fraunhofer IPMS spectral analysis systems include freshness testing of foods, sorting of plastic objects during recycling, or determining the type and concentration of raw materials in pharmaceuticals. The systems can be flexibly adapted to different spectral ranges in the design process.

Due to the combination of "single point" near-infrared spectroscopy with simple RGB imaging, maximum information determination is achieved, which enables the connection to intelligent systems with AI software. Continuous development of the system is planned. In this context, a broader spectral range in the UV range is targeted in order to make contaminations such as mold and bacteria visible.

Chemical sensors

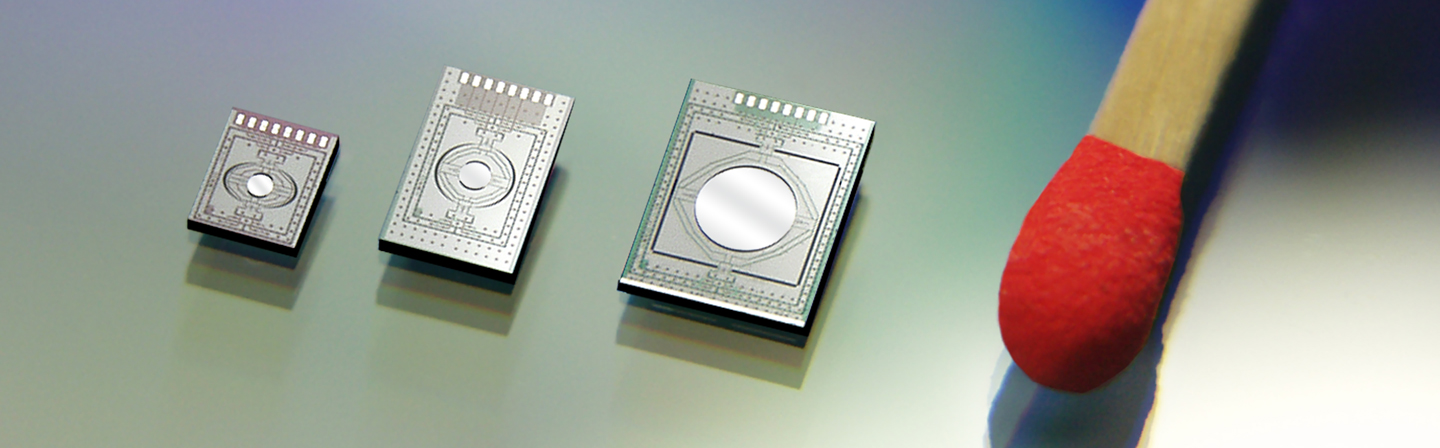

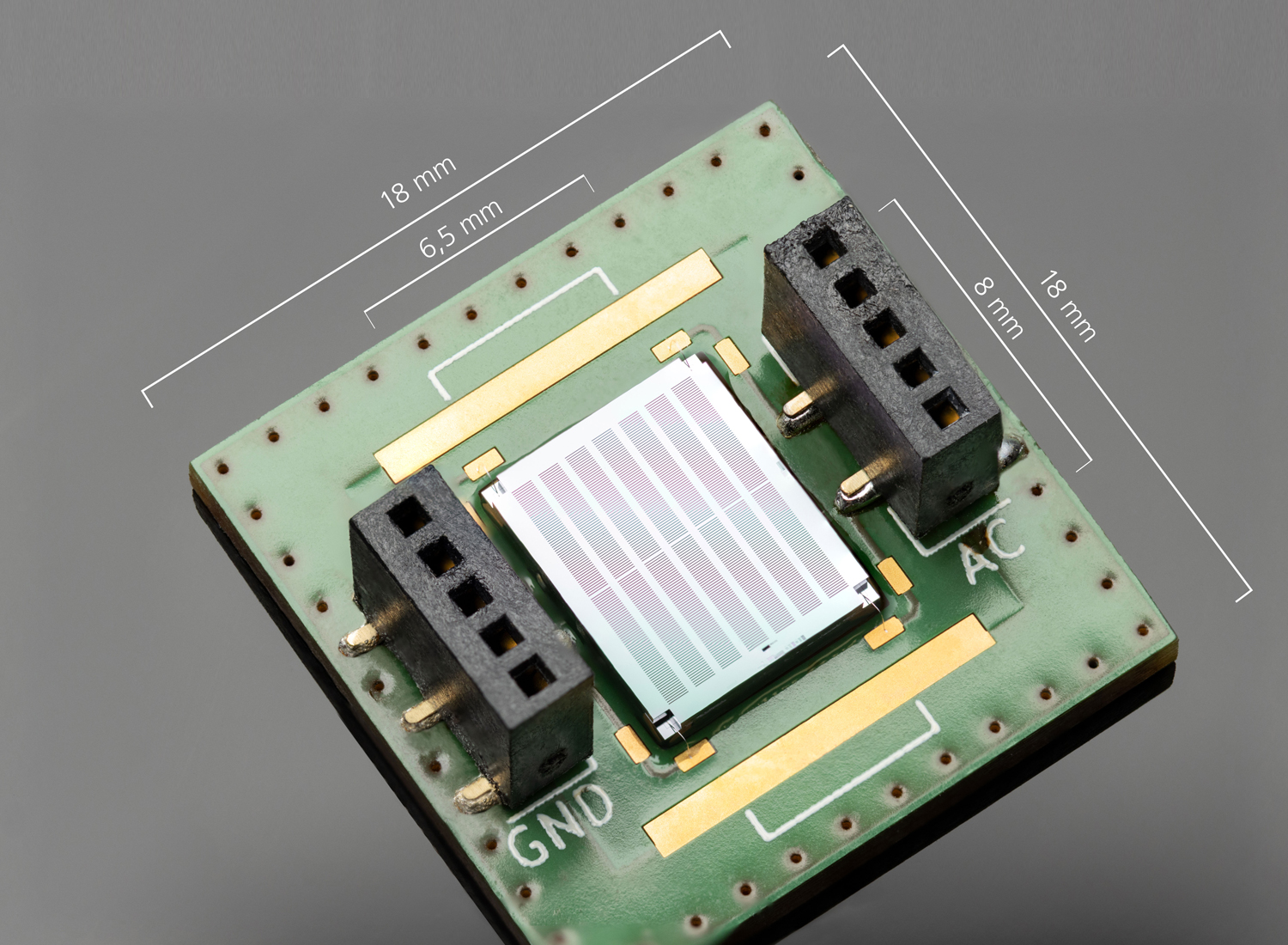

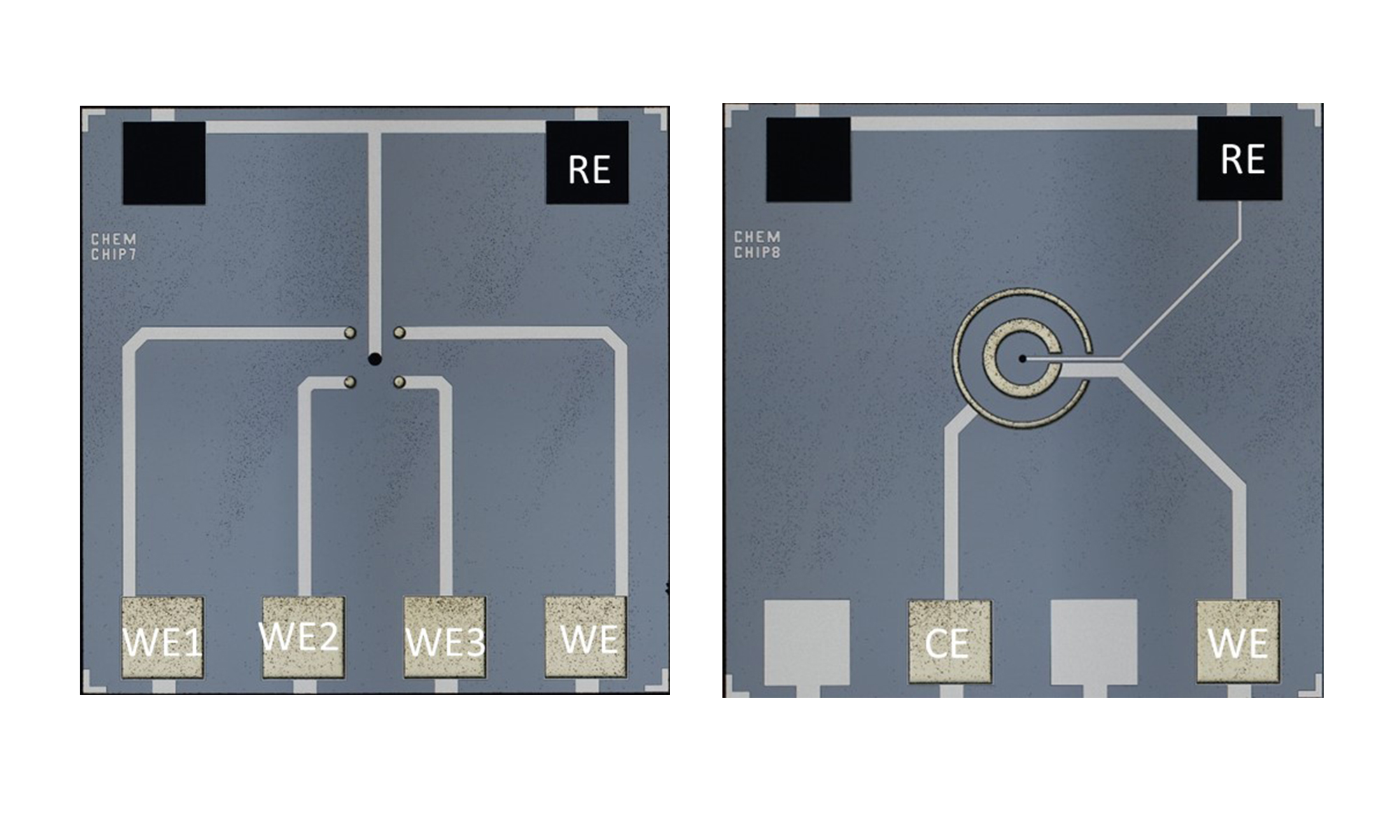

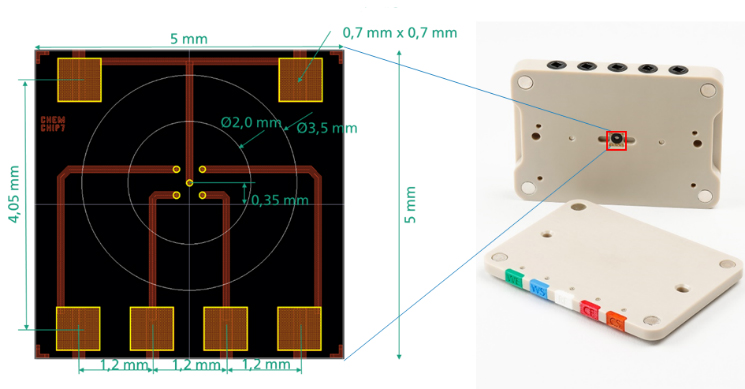

In the field of chemical sensors, the scientists of Fraunhofer IPMS present an electrochemical analytical chip which, with its microelectrodes made of gold, silver or platinum, enables numerous electrochemical analysis procedures with the smallest analysis quantities. Fields of application are, for example, the material development of organic semiconductors or offline reaction control as well as the electrochemical analysis of body fluids.

For the detection of ions, ion conductivity and temperature in aqueous solutions, the institute develops Ion-Sensitive Field-Effect Transistor (ISFET)-based sensors and a connectable integration technology. This enables, for example, pH measurement without a conventional reference electrode, which can be realized on a chip including a conductivity and temperature sensor. The chip can be stored dry and can be integrated into a Complementary Metal-Oxide-Semiconductor (CMOS) environment. Modification of the sensor layers also makes it possible to adjust the sensitivity for specific ions or molecules. At the accompanying congress to SENSOR+TEST, researchers from Fraunhofer IPMS will present the current state of developments in the thematic lecture "CMOS Based Integration Technology for Solid State pH-Measurement" (conference lecture B1.3 on May 9 at 12:20 pm).

Fraunhofer IPMS is also working on the further development of an ion mobility spectrometer (IMS), which is to be used in the future for the portable and rapid detection of relevant gases. The technology enables the detection of ionizable analytes in the ppm and ppb concentration range directly in air and is to be used in particular in environmental, food and biomedical analysis. The detectable substances originate, for example, from the group of volatile organic components (VOCs) such as acetone or toluene, which are of great importance in marker recognition or pollutant detection. For this trace gas analysis, Fraunhofer IPMS has developed a modular component that can be used with customers and cooperation partners for application-specific product developments. The underlying unique concept of component, technology and system integration, goes beyond existing solutions on the market and therefore promises to address innovative solutions in the field of gas sensor technology in the future.

Due to their small size, the development of mobile devices enables measurements directly on site, for example to detect harmful emissions at critical locations or to support medical personnel in diagnostics or treatment. In addition, access to Micro-Electro-Mechanical Systems (MEMS) technologies allows IMS chips to be realized cost-effectively in large quantities. The goal is to provide mobile devices that are widely used by laypersons and deployed within diverse application scenarios.

Ultrasound sensor technology

In the field of ultrasonic sensor technology, Fraunhofer IPMS is developing so-called CMUTs, Capacitive Micromachined Ultrasound Transducers, which can generate vibration frequencies down to the lower MHz range. Areas of application include predictive maintenance in conjunction with edge AI, gesture recognition and control of equipment, and distance detection as an alternative to optical or radar systems. This involves measuring changes in the distance from the hand to the sensors over time. At the booth, the institute will present the procedure for determining hydrogen concentrations in gas mixtures up to 100%.

CMUTs are also used in the medical field. On the trade fair the Fraunhofer IPMS presents the demonstrator of a spirometer. The system for analyzing lung function is part of an AI-controlled, decentralized patient monitoring system. The advanced CMUT ultrasound sensor technology enables an important contribution to the development of a mobile and powerful spirometer.

Fraunhofer IPMS exhibits at SENSOR+TEST in Nuremberg from May 9 to 11 at booth #1-317.

Fraunhofer Institute for Photonic Microsystems

Fraunhofer Institute for Photonic Microsystems