Bundling Clean Rooms, Strengthening Expertise

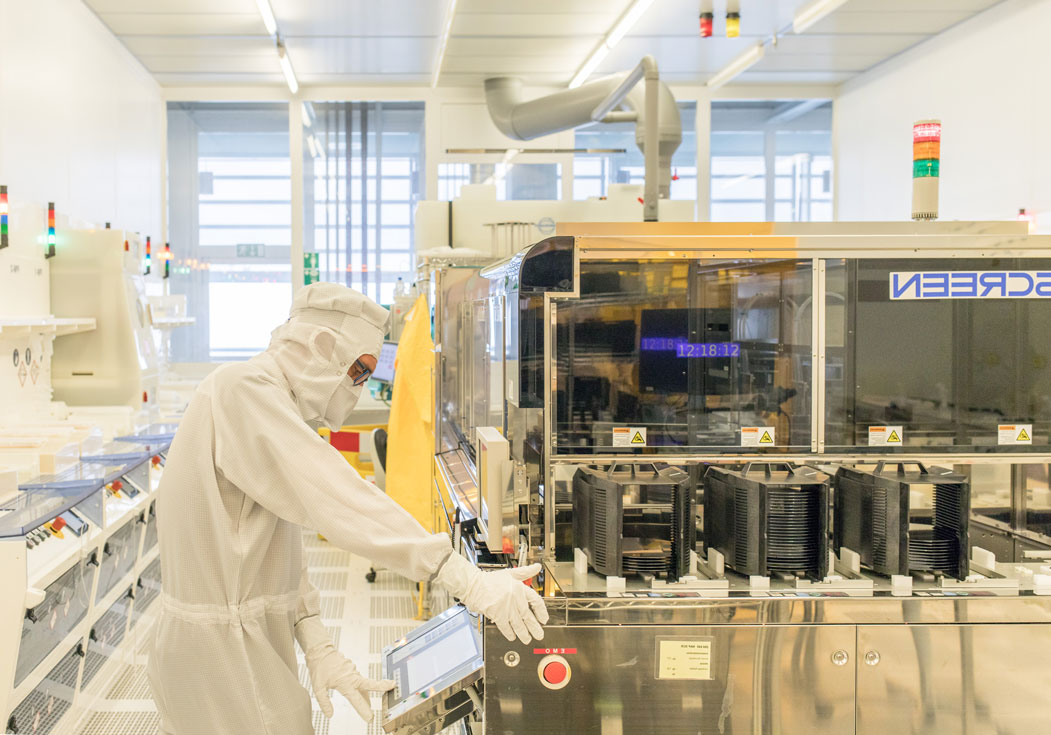

The institutes of the Fraunhofer Group for Microelectronics are growing even closer together. A new clean room strategy calls for silicon-based technologies to be clustered at two main and five focus sites for 200 mm developments and one site for 300 mm research.

In addition to Fraunhofer IPMS, IMS, EMFT, ISIT, IZM, IISB, and ENAS are involved. The aim is to provide customers from industry and science with technology offerings along the entire value chain and technology readiness level. The main sites are clean rooms that offer fully integrated process flows or technologies and have extensive systems and equipment. Fraunhofer IPMS in Dresden and Fraunhofer ISIT in Itzehoe are planned for the two main 200 mm sites. Focus clean rooms concentrate on specialized equipment (e.g., to explore novel materials). Fraunhofer IMS, EMFT, ENAS, IISB, and IZM will operate these focus clean rooms. The only 300 mm site is located in Dresden and is supported by Fraunhofer IPMS and IZM's institute branch “All Silicon System Integration Dresden” (ASSID).

As a basis for the clean room strategy, the portfolios of the institutes were coordinated or consolidated, and the first concrete steps for the transfer of equipment and processes between the network institutes were identified. In addition, further cooperation opportunities for complementing and expanding the technological offering were discussed. With this new set-up, Fraunhofer IPMS will greatly expand its 200 mm CMOS activities and broaden the range of technological offerings with a focus on MEMS-on-CMOS integration. The Institute will focus on higher Technology Readiness Levels up to pilot production (TRL3/4 to 8). Non-CMOS compatible materials are being researched in collaboration with the focus sites. In 300 mm technology, the joint site with Fraunhofer IZM-ASSID will lead to the completion of the value chain, thereby offering customers an attractive development spectrum.

In total, Fraunhofer IPMS will thus offer individual processes, modules, components, and research and development to pilot production as well as system, material, and process evaluations for and with industrial partners – all with equipment and an industry-standard clean room operation for 200 and 300 mm. The merging of the institutes from the Fraunhofer Group for Microelectronics also requires “digital togetherness”. As part of Research Fab Microelectronics Germany, a joint Manufacturing Execution System (MES) was procured for the joint control of the clean room infrastructure. This facilitates the comprehensive exchange of data and substrates and speeds up evaluations. Of course, the two clean rooms of Fraunhofer IPMS will also take part. Thomas Zarbock, head of the 200 mm clean room at Fraunhofer IPMS, gives an outlook on the future in an interview:

What is the advantage of a common MES?

The MES flanks the closer collaboration of institutes within the framework of the clean room strategy. It enables a standardized exchange of information and data as well as substrates or wafers at the specialist level between the institutes. The technological capabilities available across the various clean rooms can thus be tapped and mutually used much more easily through the MES. It also ensures that information on material processing status, throughput times, quality status, and contamination aspects can be exchanged in a standardized manner and displayed transparently. And what is just as important: The system gives colleagues a common “language” and thereby makes it much easier to communicate with each other and emphasizes common ground as the basis for open and trusting collaboration.

How far along are you with the integration at Fraunhofer IPMS?

Here we need to look at two perspectives. First, each institute has a local installation of the MES for its own clean room. There is also an “Enterprise MES” in the software package; this enables cross-site collaboration and represents the interlocking between the institutes. From the perspective of the “Enterprise MES”, the first – initially fictitious – cross-institutional substrate processing operations were successfully simulated. From the second perspective, I would like to give a brief overview of the status of the local installation at Fraunhofer IPMS.

Converting a fab with deeply integrated inventory MES during ongoing operation (as is the case at Fraunhofer IPMS) can be likened to open-heart surgery. A particular challenge for us is the replacement of classic ERP functionalities (e.g., materials management) which were mapped in the previous MES. These must now be transferred to SAP – as the central ERP system of the Fraunhofer Society – at the same time as the new MES is implemented.

The first concrete steps for system connection and mapping of business processes in the new MES have been completed. However, the detailed work is quite complex, which is why we are behind our implementation schedule from a time perspective. We aim to create all the conditions needed to map all substrate processing in the clean room via the new MES by the beginning of 2023 and to implement transparency from the perspective of quality assurance.

What will the research clean room of the future actually look like?

I see two major trends here: Environmental friendliness and agility. We would like to support the goal of the Fraunhofer Society of operating in a climate-neutral manner by 2030. We have already started the first analyses and we know the CO2 footprint of our MEMS clean room.

We also want to become more agile so that we can respond more flexibly to customer requirements and have the necessary freedom for research and development. Bringing both aspects together will be quite exciting because there are definitely intrinsic conflicting goals here.

Fraunhofer Institute for Photonic Microsystems

Fraunhofer Institute for Photonic Microsystems