Capacitive Micromachined Ultrasonic Transducer

Ultrasonic transducers can both send and emit ultrasound waves - and can therefore act as sensors and actuators at the same time.

They are established for low-interference monitoring and analysis of static and dynamic processes in industrial testing and automation technology. Another field of application is medical diagnostics, where ultrasonic sensors are used.

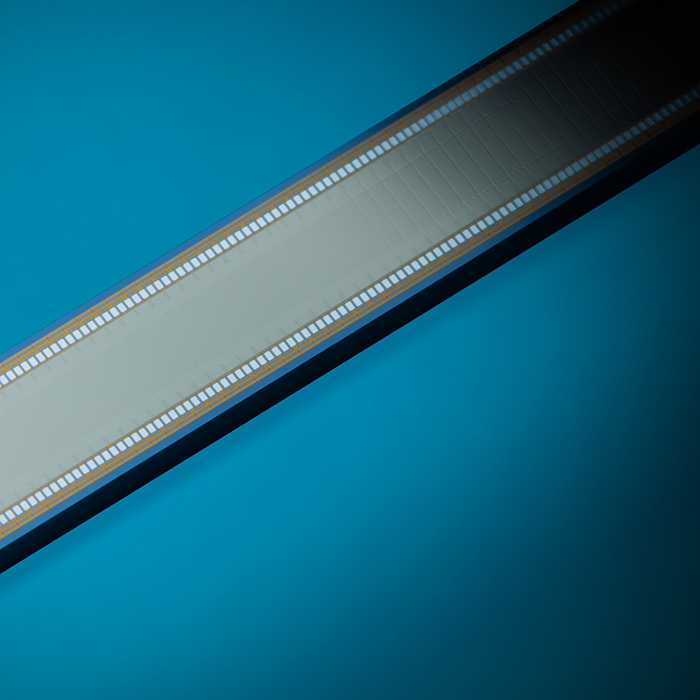

Capacitive Micromachined Ultrasonic Transducer (CMUT)

Capacitive micromachined ultrasonic transducers (CMUT) are miniaturised sensor structures whose electrostatic operating principle enables the transmission and detection of ultrasonic waves. This new generation of ultrasonic transducers is manufactured using semiconductor technology processes and thus enables great flexibility in sensor design with high precision and reproducibility in the manufacturing process for single and multi-channel systems.

Features of the CMUTs at Fraunhofer IPMS:

- wide range of elements with different frequencies (> 400 kHz)

- high acoustic bandwidth (> 100% in immersion; > 20% in air)

- high spatial resolution (submillimetre scale)

- low acoustic losses

- extreme miniaturisation (≤ 1 mm³).

In addition, the manufacturing process and the CMUT elements do not contain any toxic substances (including lead), and the Fraunhofer IPMS capacitive transducers are therefore RoHS compliant.

Lateral CMUTs

L-CMUTs are a development of the MUT at Fraunhofer IPMS which differ from classical electrostatically driven CMUTs in their design. Instead of a membrane, the volume of the chip is used for sound generation by means of laterally (L) moving elements. This results in potentially high specific sound pressures, high bandwidth, and significantly lower frequencies for long ranges in air that can be achieved with MUT.

Typical characteristics of L-CMUTs:

- Frequency: from audible sound range: 20 kHz to 300 kHz

- Range: centimeters to a few meters

- Resolution: centimeters to millimeters

- Media: gaseous

Fraunhofer Institute for Photonic Microsystems

Fraunhofer Institute for Photonic Microsystems