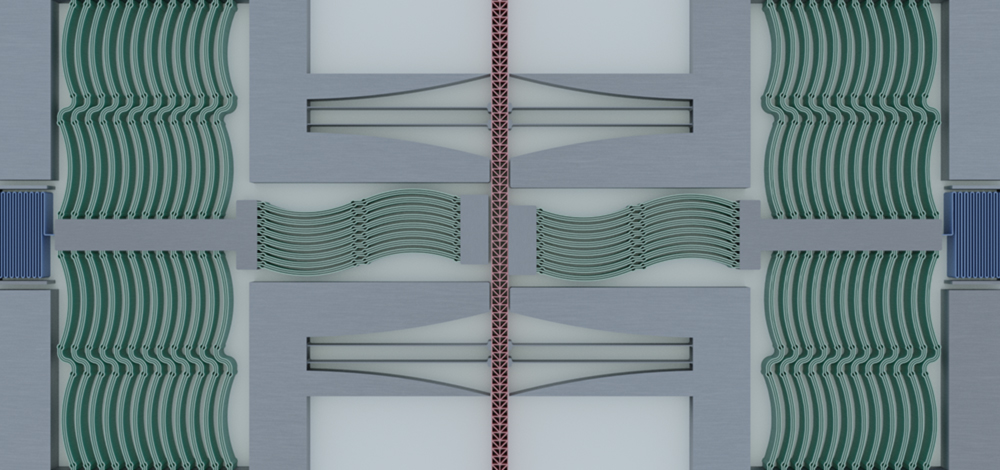

Nanoscopic Electrostatic Drive – electrostatic MEMS bending transducer

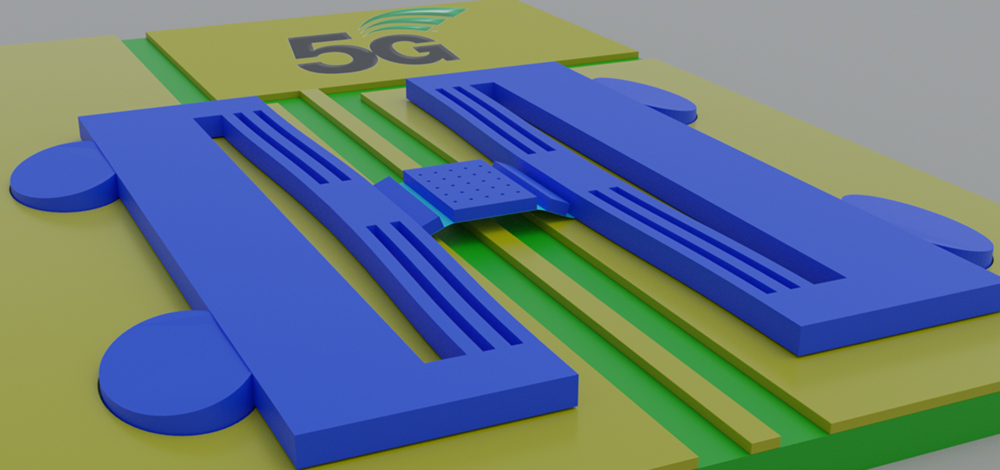

Micromachined systems are the key to the miniaturization of components and devices, without which no fast-growing technical sector can survive. These include sound transducers for audio applications, transducers for ultrasound applications, drives for microscopic pumps or valves, micromirrors and optics for beam guidance and beam shaping of light of various wavelengths, and miniaturized varactors for signal amplification and adaptation of electrical antenna networks.

The micromachined systems enable components that have a significantly smaller installation space than previously known. At the same time, the requirements for the lowest possible energy consumption of such components have increased. In the future, these components will be installed in Internet-enabled and ultra-mobile devices characterized by long battery life. Radio interfaces and processors play a key role in determining the energy requirements of such systems. Since the space for the energy supply in such devices is very limited, all components have to manage with a very small energy budget.

This also means that actuator principles are required for micro- and nanomechanical systems that are characterized by low space and energy requirements. The business unit "Monolithic Integrated Actuator and Sensor Systems" (MAS) is developing electrostatic bending actuators for this purpose, which operate according to the bimorph principle. The Nanoscopic Electrostatic Drives, NED for short, are realized in MEMS technologies and are suitable for a wide range of applications.

Fraunhofer Institute for Photonic Microsystems

Fraunhofer Institute for Photonic Microsystems