MEMS-on-PIC

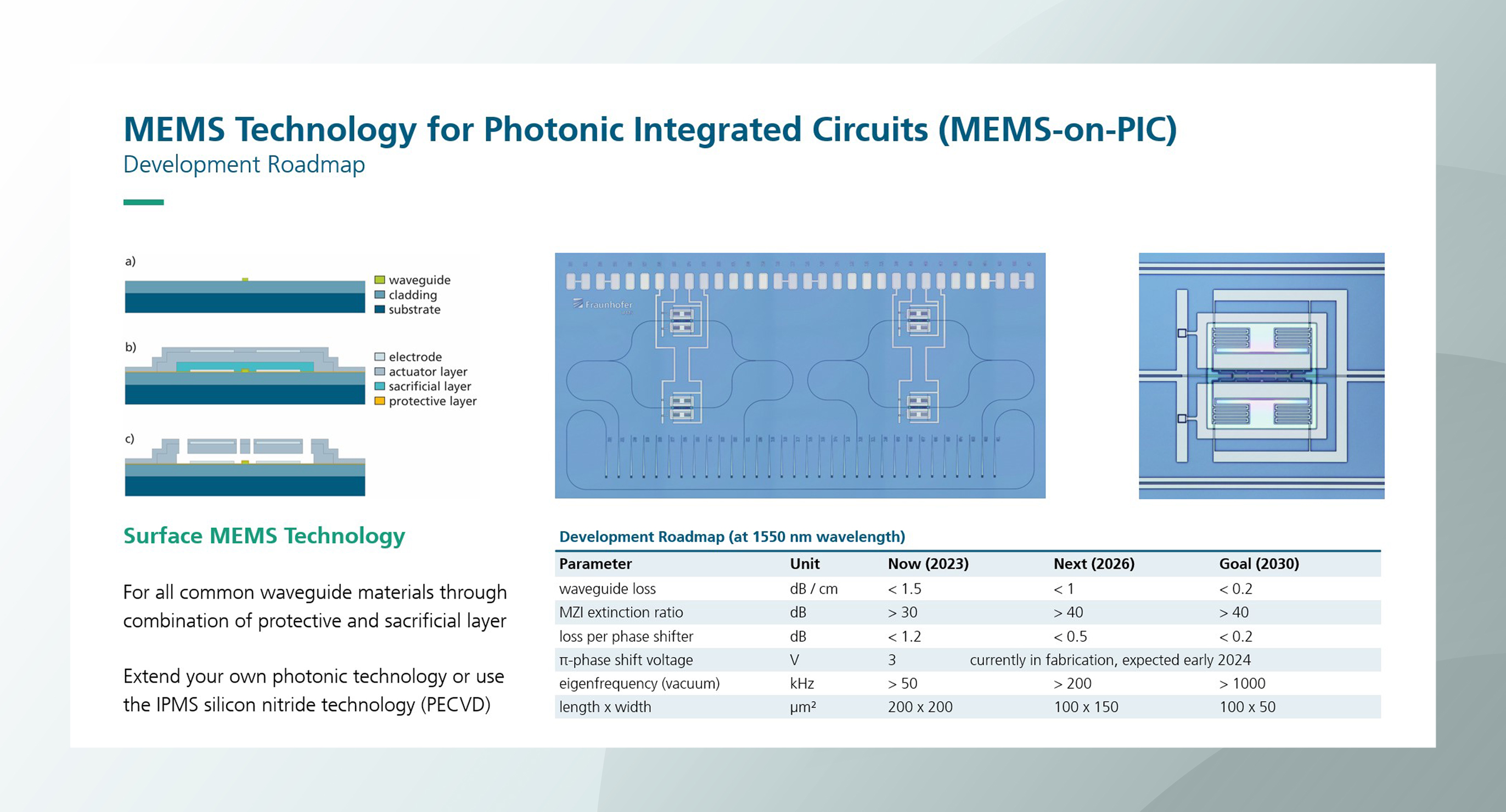

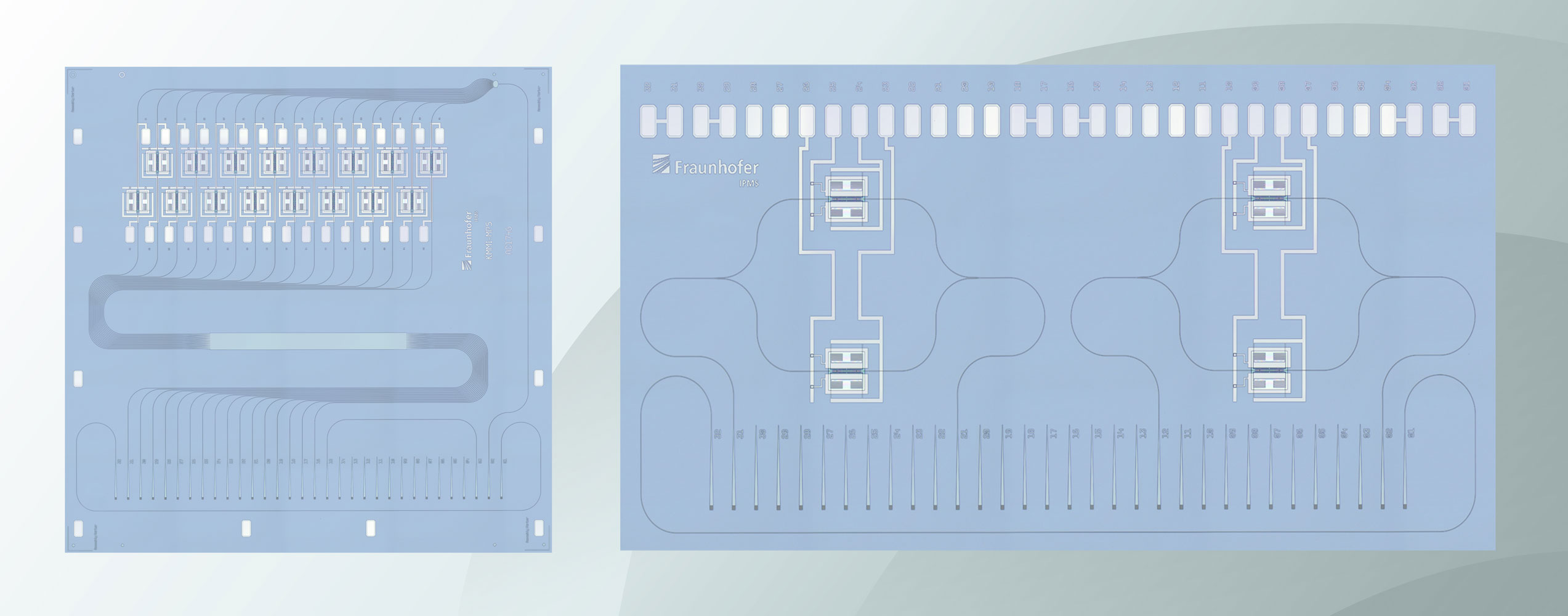

MEMS-on-PIC is the unified fabrication technology developed at Fraunhofer IPMS for MEMS photonics on all established material platforms of integrated photonic circuits (PIC).

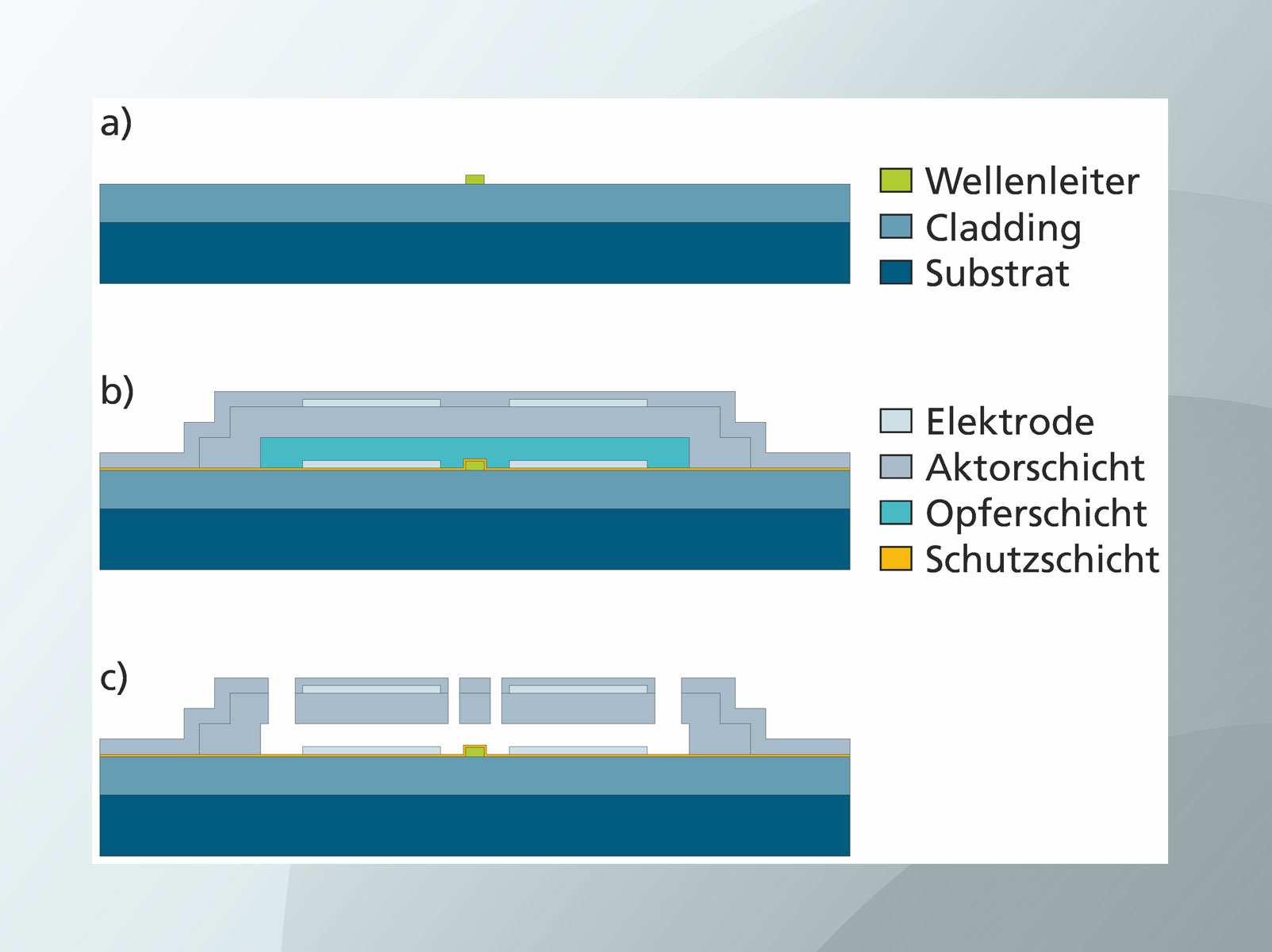

MEMS structures are built onto the waveguide layer of photonic circuits using sacrificial layer technology, which means that existing photonic circuits can also be enhanced with MEMS photonic elements.

Nanometre-thin optically transparent layers protect the waveguide layer during MEMS fabrication without significantly affecting the waveguide properties, making MEMS-on-PIC suitable for all material platforms (silicon, silicon nitride, lithium niobate, etc.).

Like the silicon nitride waveguide technology (SiN photonics platform) of Fraunhofer IPMS, MEMS-on-PIC is a CMOS-compatible 200 mm technology.

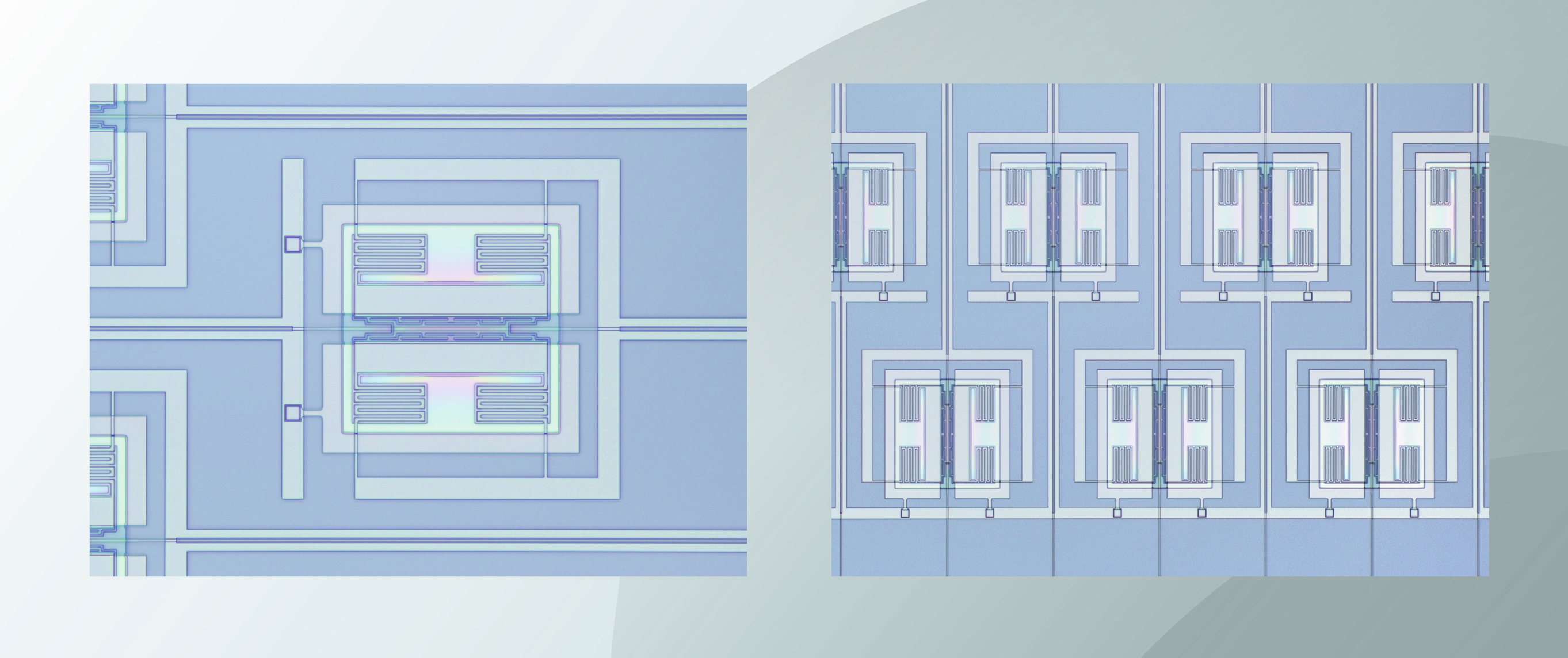

The basic principle of MEMS photonics is to change the effective refractive index of a waveguide by changing the distance between a mechanical structure and the waveguide, causing the MEMS structure to act as an optical phase shifter.

Optical phase shifters are the basic building block for photonic processors, such as those used in artificial intelligence neural networks or linear photonic quantum computers. MEMS phase shifters are distinguished by very low thermal power dissipation, enabling the design of high-density processors that can be used in cryogenic environments.

Other typical applications for MEMS photonics are optical communications, sensing and spectroscopy, where MEMS structures act as switches, modulators or filters.

Different phase shifter technologies are used depending on the requirements. For example, thermal and electro-optical phase shifters are widely used. Thermal phase shifters are distinguished by their simple fabrication and very low optical attenuation. However, high power consumption and thermal crosstalk are major drawbacks of thermal phase shifters, especially at high integration densities. Electro-optical phase shifters are a crosstalk-free alternative, featuring low power consumption and modulation frequencies in the GHz range. However, the need for heterogeneous integration limits their use. If switching time of a microsecond is sufficient for the application, or if quasi-static operation is required, drift-free MEMS phase shifters are the preferred choice due to their extremely low power consumption and very good scalability. Furthermore, they are manufactured using conventional surface MEMS technologies and can be combined with a wide variety of waveguide core materials.

Fraunhofer Institute for Photonic Microsystems

Fraunhofer Institute for Photonic Microsystems