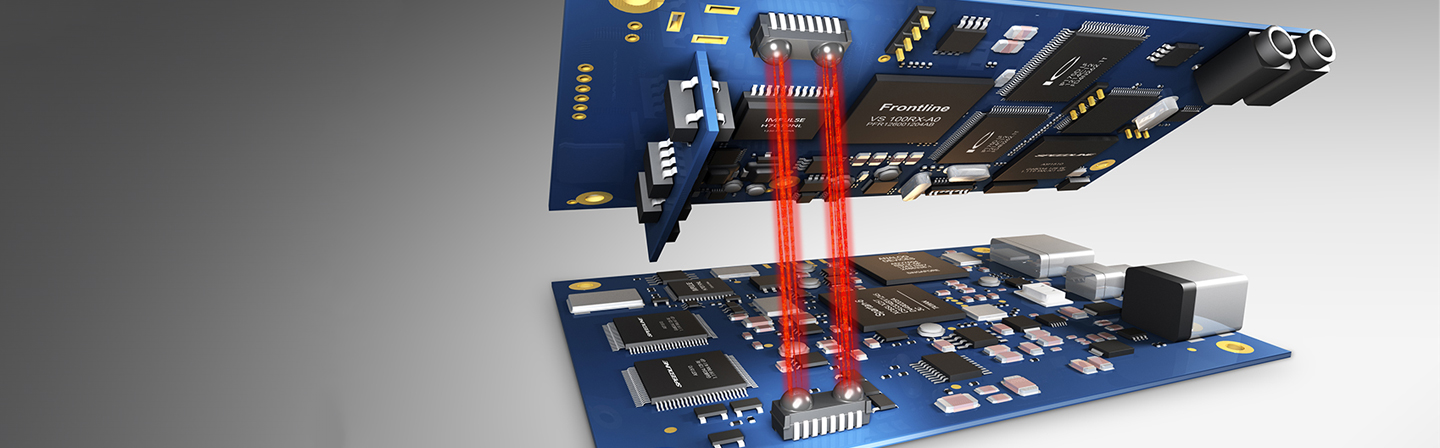

Li-Fi Optical Data Transmission

Li-Fi, or Light Fidelity, is a technology for wireless data transmission using light. The principle is simple. A modulator on the transmitter switches a light-emitting diode, or LED for short, on and off very quickly so that the human eye does not perceive it. A photodiode at the receiver picks up the light and converts it into electrical pulses. The prerequisite for this is direct visual contact between the transmitter and receiver.

Compared to other wireless communication standards, Li-Fi offers significant advantages:

- Fast wireless data transmission

- Real-time communication

- High data security due to the need for line of sight

- No interference

We offer customised projects, consulting and development services:

- Optics and transceiver development

- Optics production

- Module development

- System integration

- Characterisation & test

Fraunhofer Institute for Photonic Microsystems

Fraunhofer Institute for Photonic Microsystems