Available Characterization Methods

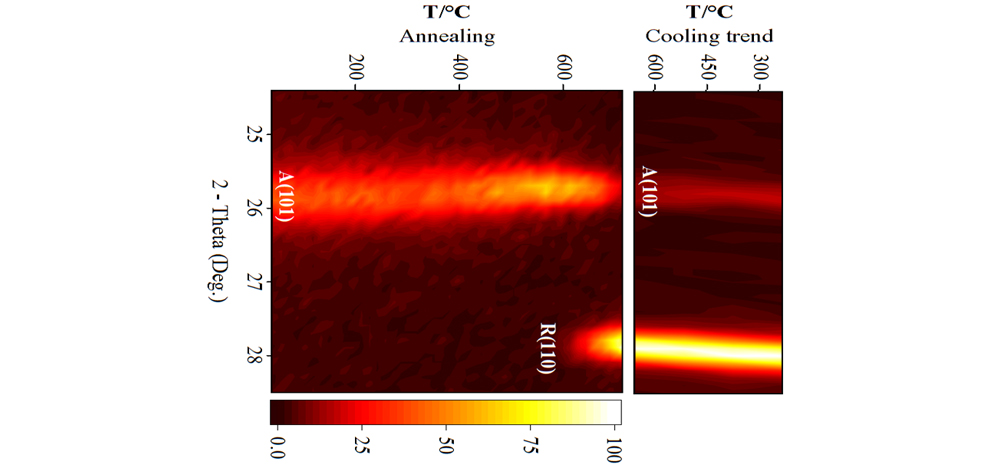

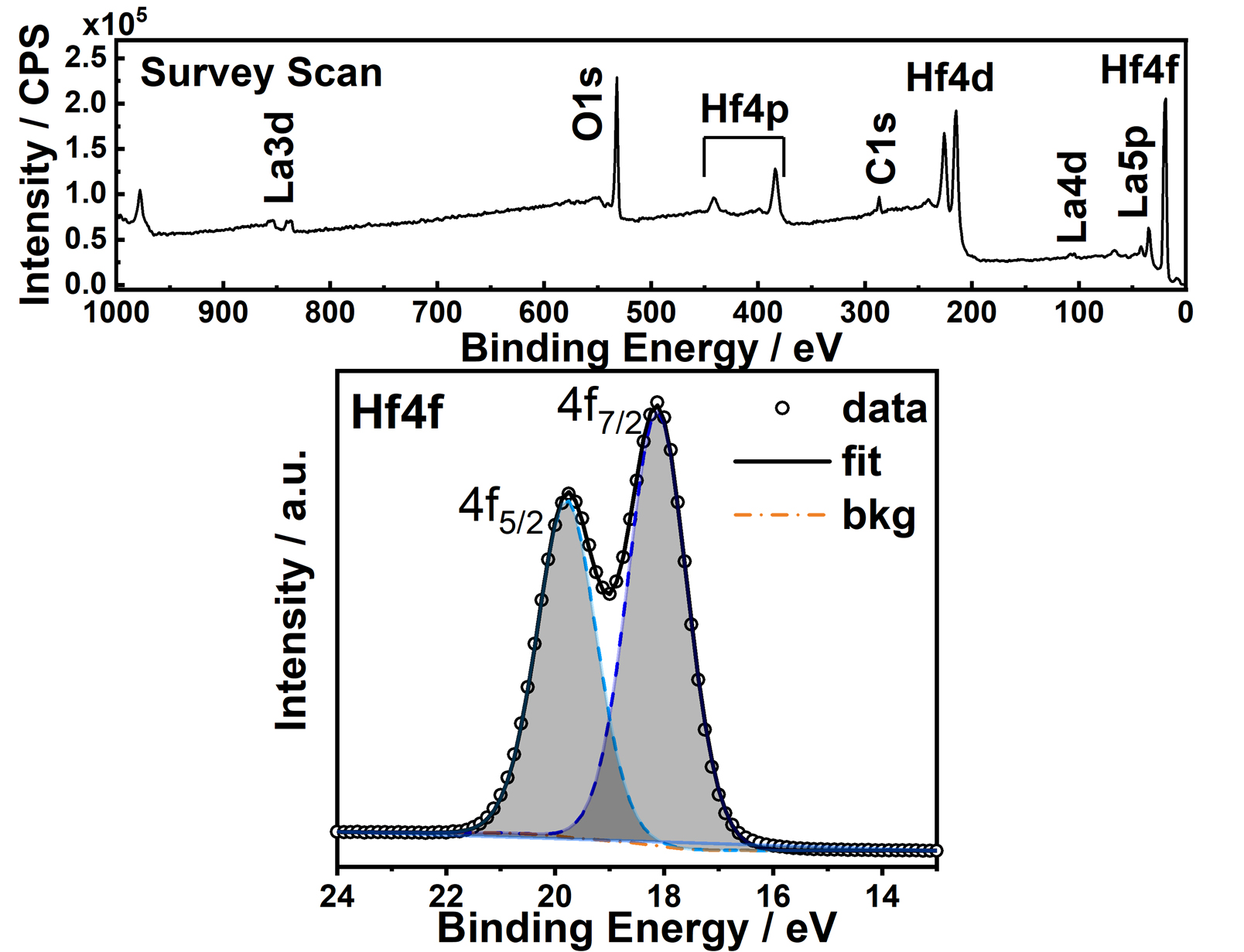

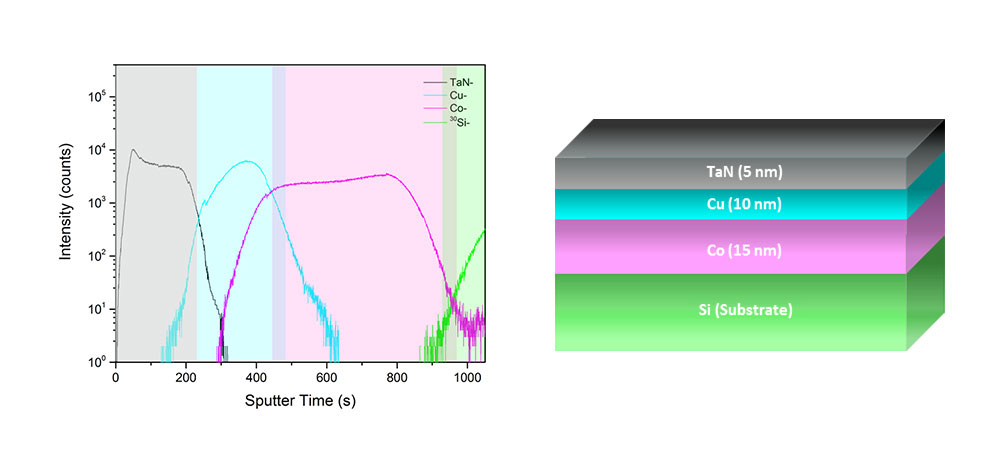

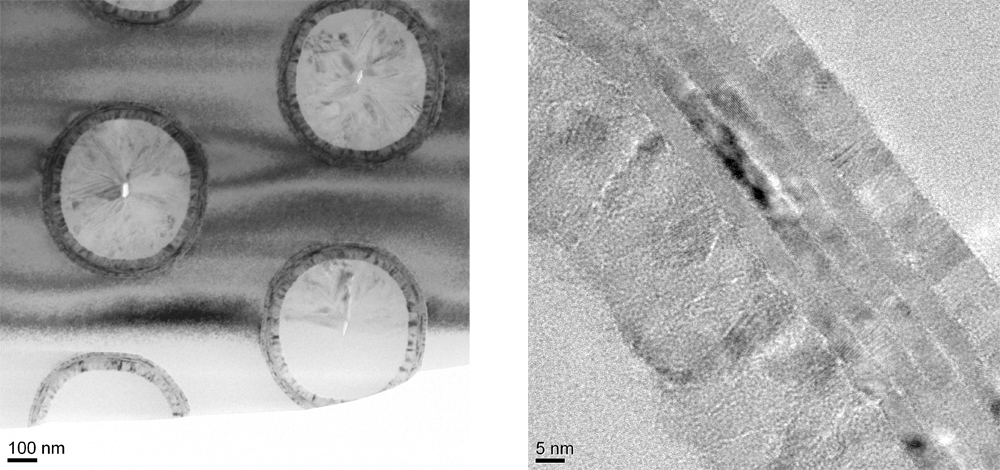

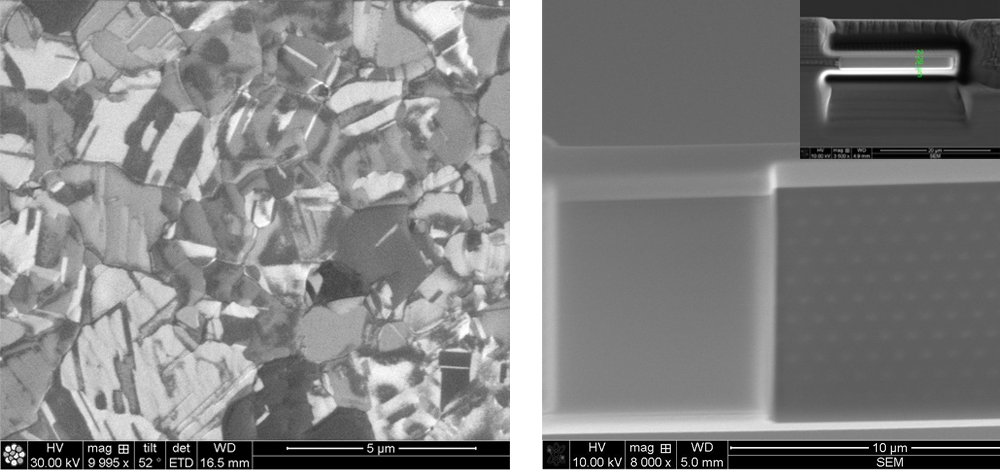

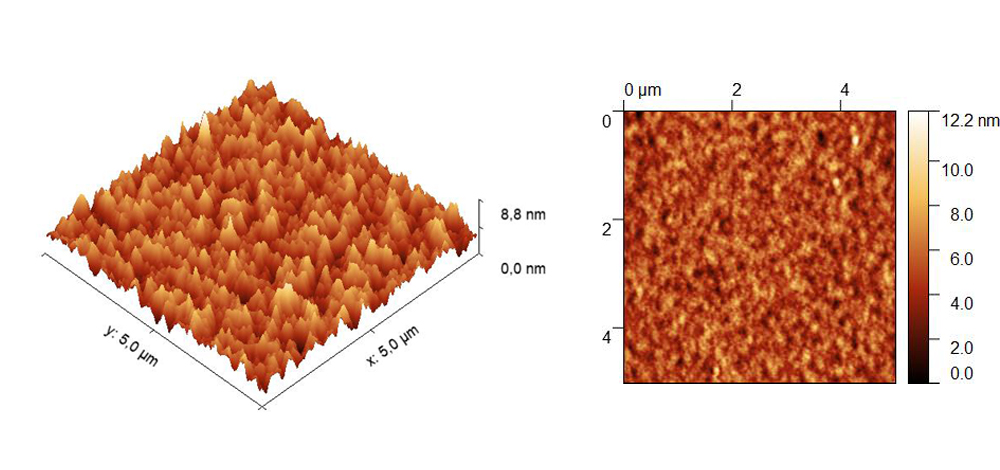

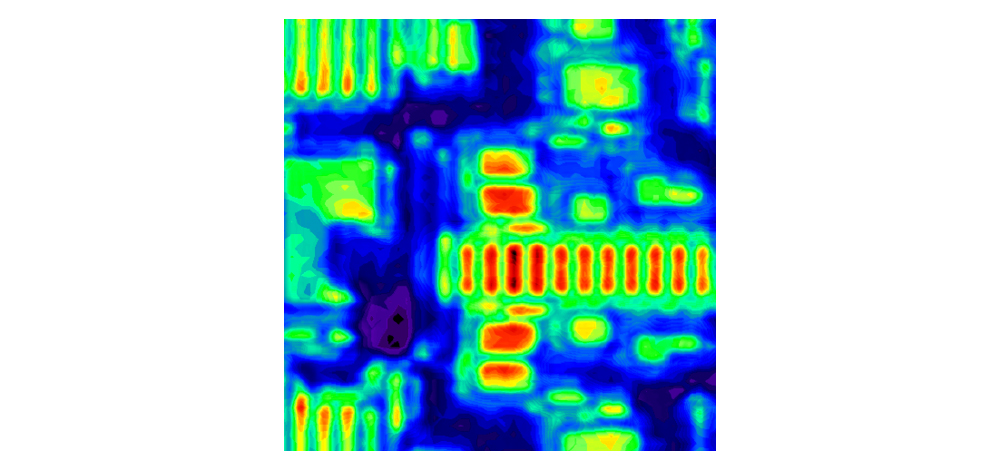

Fraunhofer IPMS offers a wide variety of analytical characterization methods in our physical failure analysis labs. We focus on wafer characterization using various X-ray methods (XPS, XRD/XRR, and TXRF), as well as Raman spectroscopy and ToF-SIMS. Furthermore, high resolution electron microscopy (SEM, TEM with EDX, EFTEM, EELS) and grain analysis (EBSD/TKD) with corresponding preparation techniques (FIB, Precision Ion Polish, Mechanical preparation) are available. Atomic and Piezoelectric force microscopy (AFM/PFM) as well as chemical etching of wafer surfaces complements the portfolio. In addition, complete electrical characterization is available here.

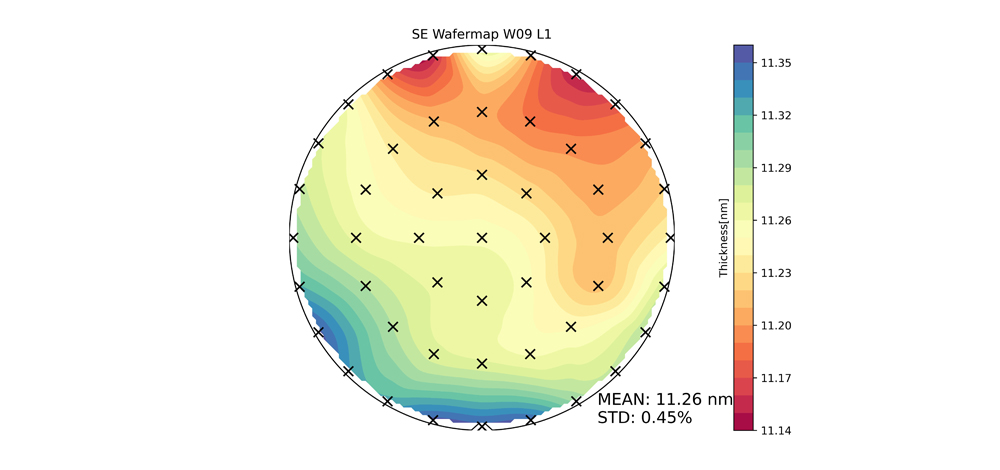

Our in-line metrology enables us to determine physical and chemical properties of structures on 300 mm wafers with, for example, X-ray diffraction, angle-resolved X-ray photoelectron spectroscopy, spectral ellipsometry and energy dispersive X-ray spectroscopy. All our tools for wafer level analysis are stationed in a class 1000 (class 6 ISO 14644-1) cleanroom environment that meets industrial standards.

Fraunhofer Institute for Photonic Microsystems

Fraunhofer Institute for Photonic Microsystems